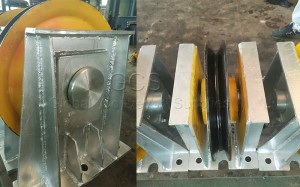

Cast Isakhelo seWheel yentsimbi yeePulleys zeHaulage

I-V-Belt Casting Pulleys

Singomnye wabavelisi abahamba phambili kunye nabathumela ngaphandle koluhlu olubanzi lweCast Iron Pulleys. Ezi pulleys zenziwa kusetyenziswa i-high-grade ekrwada, ethengwa kubathengisi abathembekileyo bemarike. Ngaphezu koko, sinikezela ngezi pulleys kumacandelo ngamacandelo afana no-a, b, kunye no-c. Oku kulandelayo ziinkcukacha ezahlukeneyo zemveliso ezibonelelwa sithi

Cast Iron V-ibhanti pulley "a" icandelo [ukusuka 1 groove ukuya kwi grooves 5]

Umxube onzima wesamente kwimizi mveliso uphosa ipuli yegroove ephindwe kabini

I-Steel Rope Sheave Pulley luhlobo lwesixhobo esibalulekileyo sokuphakamisa, silula kwisakhiwo, kulula ukuyisebenzisa. Inokutshintsha

ulwalathiso lomtsalane we-pulley kunye neqela le-pulley, inokuphinda iphakamise kwaye ihambise into enzima, ngakumbi

iqela le-pulley, kunye ne-winch, imast, kunye nomnye umatshini wokuphakamisa, osetyenziswa ngokubanzi ekwakheni. Ubalulo

kuluhlu lweemveliso ukusuka kwi-0.03t-320t.

I-Steel Rope Sheave Pulley isetyenziswa ngokubanzi kwi-Crane Manufacturer, Ugunyaziwe wezibuko, umkhumbi, i-Hoist, i-crane yelori, oomatshini bokwakha abakhulu,

Ishishini njalo njalo. Ixabiso lereferensi kuphela, nceda uqhagamshelane nathi ukuba unayo nayiphi na imfuneko.

| Igama lemveliso | amavili pulley | ||

| Izinto eziphathekayo | 45#,Q235B,Q235A,Q345A,Q345B,intsimbi yealloyi,intsimbi yekhabhoni, njl (njengesicelo somthengi) | ||

| Iyaqhuba | I-Lathing, i-milling, i-grilling, i-drilling | ||

| Unyango lobushushu | Ukunciphisa, ukuguga, ukuqina, kunye nokuqina | ||

| Max.diameter | 5000mm | ||

| Ubuninzi.ubude | 8000mm | ||

| Max. ukunyamezelana | ±0.2 | ||

| Max. ubunzima | 10T | ||

| Uhlobo | Ngokwemizobo | ||

| Ukuhlolwa | ukuhlolwa kobungakanani, uvavanyo lokusingqongileyo lwangaphandle, uhlolo olubonakalayo, uhlolo olungenayo, ukuhlolwa kwemveliso egqityiweyo, ukufunyaniswa kwesiphene | ||

| Ixesha lokuzisa | 30-90 iintsuku | ||

Cast Isakhelo seWheel yentsimbi yeePulleys zeHaulage

Ividiyo yeVili yentsimbi yokuphosa yeHaulage Pulleys

I-GCS inelungelo lokutshintsha ubungakanani kunye nedatha ebalulekileyo nangaliphi na ixesha ngaphandle kwesaziso. Abathengi mabaqinisekise ukuba bafumana imizobo eqinisekisiweyo evela kwi-GCS phambi kokuba bagqibezele iinkcukacha zoyilo.

Ukukhethwa komhambisiirola

Irola yokuhambisaisetyenziselwa ukuxhasa ibhanti lokuhambisa kunye nezinto ezikwibhanti, ukunciphisa ukuchasana kokusebenza kwebhanti lokuhambisa, ukuqinisekisa ukuba i-sag yebhanti yokuhambisa ayidluli imigaqo yobugcisa, kwaye yenza ibhanti lokuhambisa lisebenze kakuhle kwindlela echazwe kwangaphambili.

I-roller ngokusetyenziswa kwayo yahlulwe kakhulu kwi-carrier roller, i-return roller, i-impact roller kunye ne-aligning roller. I-Roller yenye yezona zinto zibalulekileyo ezichaphazela ukusebenza kwe-conveyor, i-accounting malunga ne-30% ~ 40% yomgangatho we-conveyor epheleleyo, i-25% ~ 30% yexabiso le-conveyor yonke, kwaye iyona nxalenye ephambili yolawulo lwemihla ngemihla, ukukhuselwa kunye nokutshintshwa. Ukucwangciswa kunye nokukhethwa kwe-roller kunempembelelo ebalulekileyo ekusebenzeni okuqhelekileyo komthumeli, umsebenzi ozinzile, ukusetyenziswa kwamandla kunye nexabiso le-conveyor yonke. Ngokukodwa kwimeko yesantya esiphezulu sebhanti, iimfuno ze-roller ziba nzima ngakumbi.

Njengoko icandelo eliphambili le-conveyor, i-roller iye yaqina ngakumbi kunye nokuqhubela phambili kwesantya sebhanti. Izinto eziphambili ezichaphazela ukusebenza kwesantya esiphezulu se-roller zixabiso elibalekayo kunye nexabiso lokumelana nokujikeleza. Xa i-roller isebenza ngesantya esiphezulu, isakhiwo sokutywinwa se-roller siya kuchaphazeleka kubushushu kunye nezinye izizathu. Ukucwangciswa kwesakhiwo se-roller-speed-speed roller kucetywayo kweli phepha.

1.Sisakhiwo ealing ofrngaphezulu

Isakhiwo sokutywinwa siyinto ebalulekileyo echaphazela ubomi bokusebenza kunye nokumelana nokusebenza kwe-roller. Zimbini iindlela eziphambili zokutywinwa kobume beerola kwimarike:

(1) Ukutywinwa okungabanjwanga (okufana nelabyrinth seal). Ukuchasana nokusebenza kolu hlobo lokutywinwa kuncinci, kodwa ngenxa yobukho bengxabano yangaphakathi xa usebenza ngesantya esiphezulu, ngokuqinisekileyo kuya kukhokelela ekuveleni kobushushu. Ngokutshintsha koxinzelelo lomoya, amasuntswana othuli angena kwisigxina sotywino kunye nenkqubo yokuphefumla, ebangela ukuba ukuthwala kusebenze kwimeko yokuphazamiseka kokungqubuzana, kwaye kwandise ukunxiba kwebherethi.

(2) Ukuchukumisa uhlobo lwetywina. Umphumo wokutywina ungcono kunohlobo olungathinteliyo, kodwa ukuchasana okusebenzayo kukhulu.Kwimeko yokushisa okukhulu kunye nokuhluka koxinzelelo kunye nokusabalalisa okungalinganiyo, i-deformation elastic yomlomo wokutywina nayo ayihambelani, okubangela ukuba kubekho isiphumo esibi sokutywinwa.

Akulungele ukongeza umphumo wokutywina kuphela ngokudibanisa inani leepaseji zokutywina kunye nobude bokutywina. Isakhiwo sokutywinwa kwe-labyrinth ye-gap yokuqala ejikelezayo sisitshixo sokujongana nengxaki yokutywinwa, iingxaki ze-gap, i-slime okanye amanzi aya kumpompoza kumjelo we-labyrinth wangaphakathi, obangela ukungaphumeleli kwe-roller, inombolo ye-maze enjalo ayinantsingiselo.

I-roller ecetywayo kweli phepha ithatha isakhiwo esidibeneyo se-axial labyrinth seal kunye ne-touch seal, kunye neempawu zayo zilandelayo:

(1) Inani leepaseji zokutywinwa kwe-axial labyrinth seal ayichatshazelwa ngumlinganiselo we-radial wokuthwala, kwaye unokongezwa ngokufanelekileyo. Umphezulu wokutywina we-axial labyrinth ukwicala elifanayo njengamandla e-centrifugal yokuhamba kwamanzi. Amanzi angenile kwi

itywina xa i-roller ijikeleza iya kumpompoza ukuya phezulu kwi-labyrinth ecaleni kwendawo yokutywina phantsi kwempembelelo ye-centrifugal force. Ukuze kuphuculwe umphumo, umphezulu wendandatho yokutywina yangaphakathi unokuqwalaselwa ukukhetha isakhiwo se-arc setyhula.

2 Umsesane wokutywina we-NBR/PA6 izinto, ubunzima obulula, ukuxhathisa ukubola, i-coefficient ye-friction incinci kunezinye iiplastiki zobunjineli.

(3) yongeza iringi yeconvex kwiringi ye-baffle yangaphakathi (jonga uMfanekiso 1), tshintsha isalathiso sentshukumo ye-axial xa uthuli okanye amanzi engena kumsantsa weringi yangaphakathi. Xa i-roller isebenza ngesantya esiphezulu, i-vacuum iya kwenziwa phakathi kweringi ye-convex kunye neringi ye-baffle yangaphandle ukuqinisekisa isiphumo sokutywinwa.

Iimpawu ze-2.Process kunye nokukhethwa kwezinto eziphathekayo

I-radial run out of the roller ikakhulu ixhomekeke kwimpazamo ye-radial ye-cylinder, umgangatho wesihlalo sokuthwala kunye ne-coaxiality yenkqubo yendibano. Ixabiso le-radial run out of roller linempembelelo enkulu kumsebenzi ogudileyo we-conveyor, ngakumbi xa ixabiso le-radial run-out likhulu kakhulu ngesantya esiphezulu, ibhanti lokuhambisa liya ku-oscillate ngobundlobongela kwaye lichaphazele umsebenzi oqhelekileyo.

Okwangoku, ininzi ye-roller ye-roller ithathelwa indawo yimibhobho yensimbi, enzima kumgangatho. Umgangatho wemibhobho, i-ovality kunye nokunyamezela kwe-diameter yangaphandle akukho lula ukuqinisekiswa, ngokukodwa ubukho bokungaqhubeki kwesakhiwo sombhobho kuchaphazela i-coaxiality, kwaye kulula ukubangela ukuba i-roller ibe yi-eccentric. I-vibration ye-periodic iya kwenzeka ngenxa yamandla e-centrifugal ngexesha lenkqubo yokusebenza, eya kuchaphazela ukusebenza kakuhle kwebhanti yokuhambisa.

3. Ukukhetha ukuthwala i-roller

Ubomi bokusebenza kwe-roller ikakhulu buxhomekeke kwi-bearing and seal.Abaninzi abangasebenziyo kwiimarike basebenzisa iibheringi ezinkulu zokucoca. Xa kuthelekiswa neebheringi eziqhelekileyo, iibheringi ezinkulu zokucoca zinococeko olukhulu kunye nobubanzi bebhola, ezinokunciphisa uvakalelo kwi-coaxiality kunye nokuphucula ukukwazi ukuziqhelanisa nezinto zangaphandle.

Nangona kunjalo, ukukhethwa kweebheringi kunye nokukhutshwa okukhulu kuya kuchaphazela kakhulu umthamo we-axial we-idler, ngakumbi emva kokuba isantya sebhanti sandisiwe, ukunyakaza kwe-axial bearing capacity kuya kubangela ukungalingani komsebenzi we-belt conveyor. Nangona kumaxesha anzima, kuyimfuneko ukumisa umatshini wokucoca kunye nokugqithisa ukusuka ekuqaleni.

Kweli phepha, siceba ukukhetha iibheringi zebhola zegroove ezinzulu ezinothuli olugqunyiweyo, olungenakuqinisekisa kuphela ucoceko lwangaphakathi lwebheringi, ukwandisa umthamo wokuthwala i-axial, ukunciphisa umonakalo oqhelekileyo wokuthwala okubangelwa yi-axial high-frequency impact force, kodwa kwakhona uqinisekise umsebenzi ogudileyo wokuthwala wandisa ubomi bokwenene bokusebenza.

Eli phepha lenze uphando olusisiseko kwii-roller ze-high-speed ukusuka kwimiba yesakhiwo, ukutywinwa, ukusetyenziswa kunye nobuchwepheshe bezinto ezintsha. I-roller ithatha isakhiwo sokutywinwa esidibeneyo esidibanisa i-axial labyrinth kunye ne-touch labyrinth, kwaye isebenzisa i-deep groove ibhola ephethe isigqubuthelo sothuli. Ukusetyenziswa kwezinto ezintsha kunye nokutshintshwa kweteknoloji yokucubungula kuqinisekisa ukuxhathisa okujikelezayo kwe-roller, ukuxhuma kwe-radial circular jumping kunye nokungenamanzi, ukutywinwa kothuli kunye neminye imisebenzi. Ngaphantsi kolwalathiso lophuhliso lwamandla aphezulu, umgama omde kunye ne-throughput-throughput conveyors, isakhiwo se-Roller esicetywayo kweli phepha sinokumelana okuncinci okujikelezayo, ingxolo ephantsi kunye nobomi obude bokusebenza, obudlala indima ebalulekileyo kumandla ophumayo we-speed conveyor.

Global Conveyor Supplies Company Limited -RS series rollers

Umphini:I-roller shaft yenziwe ngentsimbi ecolekileyo ebandayo ezotyiweyo engqukuva, engazange ifudumale kwaye icaphuke. Umatshini wokusila ochanekileyo, umatshini wokugoba we-ring ring usetyenziselwa ukusetyenzwa kweshaft, ukuze kuqinisekiswe ukuba ukufuduswa kwe-axial yerola kuphantse ukuba zero.

Umbhobho:I-roller shaft yenziwe ngentsimbi ecolekileyo ebandayo ezotyiweyo engqukuva, engazange ifudumale kwaye icaphuke. Iqokobhe le-roller lithatha umbhobho okhethekileyo we-welding, idigri encinci yokugoba, i-elasticity encinci. Yamkela umbhobho wentsimbi ophucukileyo wokusika kunye nesixhobo somatshini wangaphakathi womngxuma, ukuchaneka komatshini kuzo zombini iziphelo zombhobho wentsimbi, uqinisekise ngokufanelekileyo i-concentrically ye-roller, ukunciphisa impazamo yomatshini.

Ukuthwala:Ukuthwala i-roller kwamkela i-C3 ekhethekileyo yebhola ye-groove enzulu. Ngaphambi kokuhlanganisana, ukuthwala i-roller kuzaliswe igrisi ye-lithium kwaye itywinwe ngokusisigxina kumacala omabini, enokuqonda ukugcinwa kobomi bonke simahla kunye nokwandisa ubomi benkonzo yokuthwala.

Ukudityaniswa kwetywina:Icandelo le-roller seal lenziwe ngezinto ze-nylon, kwaye ifom yesakhiwo yi-contact labyrinth seal structure. Ukutywinwa kwangaphakathi kunye nangaphandle kwenza i-channel ye-labyrinth echanekileyo, umjelo ogcwele igrisi ye-lithium yexesha elide, ukwenzela ukuba i-roller ibe nokusebenza kakuhle kwamanzi kunye nothuli. Umatshini wokusila ochanekileyo, umatshini wokugoba we-ring ring usetyenziselwa ukusetyenzwa kweshaft, ukuze kuqinisekiswe ukuba ukufuduswa kwe-axial yerola kuphantse ukuba zero.

Indawo yokuhlala:Ukuveliswa kwezindlu ezithweleyo kwamkela imigangatho emininzi echanekileyo yokubumba isitampu esizenzekelayo ukuqinisekisa ukuchaneka okuphezulu kokuthwala kunye nokutywinwa. Iityhubhu ze-roller kunye nezindlu ezithwalayo kuzo zombini iziphelo ze-3mm iiflethi ezigcweleyo zidityaniswe ngukhuseleko lwegesi ye-carbon dioxide ngaxeshanye kunye nompu ombini we-welding machine ukubonelela ubuncinci be-70% yokungena kunye nokuqinisekisa ukuba i-idling ihlala yomelele naphantsi kwemithwalo ephezulu kunye nesantya esiphezulu.

1. Iirola ze-RS zechungechunge ze-GCS eziphezuluukuhambisa iirola.

2. I-return / carrier / trough roller inokwakhiwa okuphezulu okuchanekileyo okubandakanya ukuya kwiingxenye ezilithoba zokutywinwa, ukuqinisekisa ukuxhathisa kwamanzi kunye nothuli. Ngamatywina erabha okanye ensimbi, i-multi-groove labyrinth seals.

3. Izindlu zokuthwala kunye ne-roller tube i-welded ngokupheleleyo ukuqinisekisa uqhagamshelwano oluhle kuyo yonke i-roller. Igrisi sisithambiso esisisigxina.

4. Ngokweemfuno zomthengi, umphezulu we-roller unokupeyintwa ngawo nawuphi na umbala.

5. Izinto eziphathekayo: Ngokuqhelekileyo i-Q235 yensimbi ye-carbon (ezinikezelwe ukuhambisa i-roller), i-A3 i-shaft yokudweba ebandayo (inokuba ichanekile ephezulu ngokweemfuno ezahlukeneyo zabathengi).

6. I-roller nganye iya kudlula ukuhlolwa okungqongqo kunye nokuvavanya ukuqinisekisa ukuba ibhetshi nganye ye-roller iphezulu ngokwenene.

Nceda uzive ukhululekile ukuqhagamshelana nathi ukuze ufumane iirola zokuhambisa.

Sibuchwephesha, ubuchwepheshe obugqwesileyo kunye nenkonzo. Siyayazi indlela yokwenza umqulu wethu wokuhambisa uhambise ishishini lakho! Khangela ngakumbiwww.gcsconveyor.com I-imeyilegcs@gcsconveyoer.com

Amatyala aphumeleleyo