I-Rubber Disc Return Idler - i-China GCS yokuhambisa i-roller umthengisi

INGCACISO:

Kububanzi bebhanti: 400-2800mm

Unyango loMphezulu: I-Electrostatic Powder Coating, iGalvanization.

Umgangatho: DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR njl.

ISICELO

Ukwembiwa|Izingqusho zentsimbi|Iziko lesamente|Iziko lombane|Iziko leKhemikhali|Izibuko laseLwandle

Ugcino|njl.

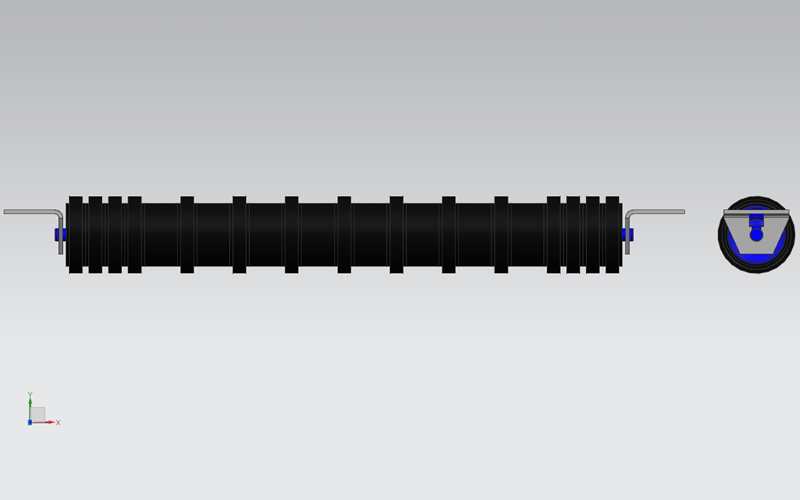

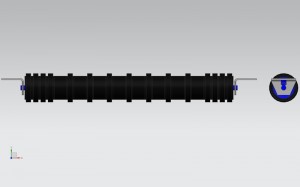

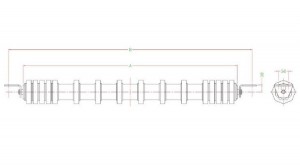

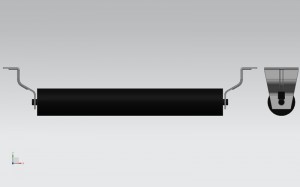

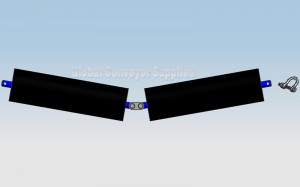

I-Rubber Disc Return Idler - SERIES RS-HRS

IRUBHA DISC UKUBUYELA IDLER NE-SPACERS-127 Diameter

| Inombolo yekhowudi. | A | B | Phelisa iDiskhi | Icwecwe leZiko | Shaft Dia. | Ubuninzi RP | IMisa iyonke |

| XX-G1-1-K0E2-0500-YY | 575 | 750 | 8 | 2 | 27 | 7.8 | 13.1 |

| XX-G1-1-K0E2-0600-YY | 675 | 850 | 10 | 3 | 27 | 9.6 | 15.3 |

| XX-G1-1-K0E2-0650-YY | 725 | 900 | 10 | 3 | 27 | 10.0 | 15.9 |

| XX-G1-1-K0E2-0750-YY | 825 | 1000 | 10 | 4 | 27 | 11.0 | 16.4 |

| XX-G1-1-K0E2-0800-YY | 875 | 1150 | 10 | 4 | 27 | 11.4 | 18.1 |

| XX-G1-1-K0E2-0900-YY | 975 | 1050 | 10 | 5 | 27 | 12.5 | 19.6 |

| XX-G1-1-K0E2-1000-YY | 1075 | 1250 | 10 | 6 | 27 | 13.6 | 21.0 |

| XX-G1-1-K0E2-1050-YY | 1125 | 1300 | 10 | 6 | 30 | 14.0 | 23.1 |

| XX-G1-1-K0E2-1200-YY | 1275 | 1450 | 10 | 7 | 30 | 15.4 | 25.2 |

| XX-G1-1-K0E3-1350-YY | 1425 | 1650 | 10 | 9 | 33 | 17.3 | 30.0 |

| XX-G1-1-K0E3-1400-YY | 1475 | 1700 | 10 | 9 | 33 | 17.7 | 30.7 |

XX-igalelo: RS okanye HRS.

Ukufumana enye imbuyekezo yobude bokwehla jonga inkqubo yokuchonga.

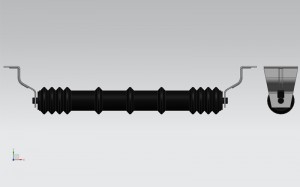

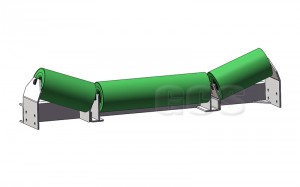

RUBBER DISC REturn IDLER NE-SPACERS-152178 Diameter

| Inombolo yekhowudi. | A | B | Phelisa iDiskhi | Icwecwe leZiko | Uthotho 45 | Uthotho 50 | ||||

| Shaft Dia. | Ubuninzi RP | IMisa iyonke | Shaft Dia. | Ubuninzi RP | IMisa iyonke | |||||

| XX-G1-1-K0E2-0600-YY | 675 | 850 | 6 | 2 | 38 | 13.8 | 24.2 | 38 | 15.4 | 25.8 |

| XX-G1-1-K0E2-0650-YY | 725 | 900 | 6 | 2 | 38 | 14.9 | 26.6 | 38 | 16.5 | 28.2 |

| XX-G1-1-K0E2-0750-YY | 825 | 1000 | 6 | 3 | 38 | 16.3 | 28.9 | 38 | 18.1 | 30.7 |

| XX-G1-1-K0E2-0800-YY | 875 | 1050 | 6 | 3 | 38 | 16.9 | 30.0 | 38 | 18.7 | 31.8 |

| XX-G1-1-K0E2-0900-YY | 975 | 1150 | 6 | 3 | 38 | 18.0 | 32.0 | 38 | 19.8 | 33.8 |

| XX-G1-1-K0E2-1000-YY | 1075 | 1250 | 6 | 4 | 38 | 19.9 | 34.7 | 38 | 21.9 | 36.7 |

| XX-G1-1-K0E2-1050-YY | 1125 | 1300 | 6 | 4 | 38 | 20.4 | 35.7 | 38 | 22.4 | 37.7 |

| XX-G1-1-K0E2-1200-YY | 1275 | 1450 | 6 | 5 | 38 | 22.9 | 39.5 | 38 | 25.1 | 41.7 |

| XX-G1-1-K0E3-1350-YY | 1425 | 1650 | 6 | 7 | 38 | 26.7 | 45.1 | 38 | 29.3 | 47.7 |

| XX-G1-1-K0E3-1400-YY | 1475 | 1700 | 6 | 7 | 38 | 27.3 | 46.6 | 38 | 29.9 | 49.2 |

| XX-G1-1-K0E3-1500-YY | 1575 | 1800 | 8 | 6 | 38 | 29.1 | 48.9 | 38 | 31.9 | 51.7 |

XX-igalelo: RS okanye HRS.

Abavelisi be-GCS roller conveyorunelungelo lokutshintsha imilinganiselo kunye nedatha ebalulekileyo nangaliphi na ixesha ngaphandle kwesaziso. Abathengi mabaqinisekise ukuba bafumana imizobo eqinisekisiweyo evela kwi-GCS phambi kokuba bagqibezele iinkcukacha zoyilo.

1.Zisetyenziselwa ntoni iirola zerabha?

Ukusetyenziswa okusisiseko kwi-roller ye-rubber kufumaneka kwiinkqubo zokwenziwa kweengubo, ifilimu, iphepha, iphepha kunye nentsimbi edibeneyo. Iirola ezigqunywe ngerabha zisetyenziswa kuzo zonke iintlobo zesikhongozeli kunye nezixhobo zokwenza izinto zokupakisha kunye noomatshini abasetyenziselwa ukugalela kunye nokusila iinkuni, intsimbi kunye ne-aluminiyam.

2.Zenziwa njani iirola zerabha?

Iirola zerabha zidla ngokuveliswa ngokuphoswa okanye ukubunjwa, kodwa zisenokwenziwa nange-extrusion. Iinkqubo zokuphosa zisetyenziswa kuphela ngeerola zerabha ezineentsimbi zetsimbi. Kule meko, ii-cores zenziwe ngenkqubo yokuphosa isinyithi njengesitampu, emva koko ziboshwe kwi-rubber coating.