Soo saaraha Roller Idler Soo saaraha 2RS Roller Carrier | GCS

Taxanaha rullaluistemadka conveyor GCS

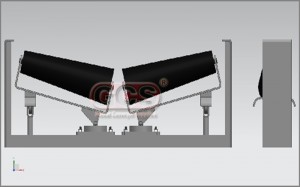

Qaabka: RS62 63 TAXANAHA

| XILDHIBAAN | PIPE Dia |

| 6204/6205 | 60/76/89/108/114/127/133 |

| 6305/6306/6307/6308/63096310/6311/6312 | 76/89/108/114/127/133/159/165/194/219 |

Roolaha RS waa badeecad qaali ah oo leh qaab dhismeed ka hortag ah oo saddex jibaaran oo si wax ku ool ah uga hortagi kara biyaha iyo boodhka. Qaabkani waxa uu quseeyaa hababka suunka qaada ee qaadi kara mug weyn iyo boodh xawli sare leh.

Sharaxaada Alaabta

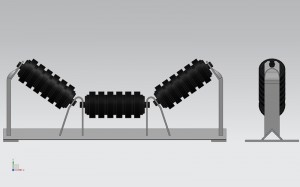

Shaqo culus oo sidda macdan-qorid aan shaqaynrullaluistemadka conveyor

Waxaan leenahaySoo Celinta Birta Roolaha, Qaadista suunka culus ee Xamuulka qaada, iyo Roller Idler-ka Macdanta suunka. Si loo daboolo baahiyahaaga, waxaanu kuu habayn karnaa qalabka wax qaada.Dhammaan rollers-ku waxay ka kooban yihiin shaabado wasakh ah oo hoose iyo sare ah, kubbadda jeexdin qoto dheer iyo tubbada ERW oo leh cidhifyada MIG alxanka leh. Shafts ayaa loo talaabsadaa sidii loo baahnaa.

| QAABKA | |

| Dhexroorka | φ89, φ102, φ108, φ114, φ127, φ133, φ139, φ152, φ159, φ165, φ194 |

| Dhererka | 145mm-2800mm |

| Tube | Q235(GB), Q345(GB), alxanka leh DIN2394 taagan |

| Shaf | A3 iyo 45# bir (GB) |

| Qaadashada | Keli & Laba Jibaaran Deep Groove Ball Bearing 2RS&ZZ oo leh fasax C3 |

| Guri-ku-fadhi | Shaqada saxaafadda qabow waxay ku habboon tahay saxnaanta ISO M7Deep Press steel oo leh walxo ceeriin ah oo ku habboon DIN 1623-1624 heerka |

| Saliidda Saliidda | Fasalka 2 ama 3 dufan lithium ah oo raagaya |

| alxanka | Dhammaadka alxanka gaaska gaashaanka isku dhafan |

| Rinjiyeynta | Rinjiyeynta caadiga ah, rinjiyeynta galvanized kulul, rinjiyeynta korontada taagan, rinjiyeynta dubay |

| Dhexroorka Tube-ka | Dhererka Tube-ka | Nooca Dhalmada | |

| mm | inji | mm | |

| 63.5 | 2 1/2 | 150-3500 | 6204 |

| 76 | 3 | 150-3500 | 6204 6205 |

| 89 | 3 1/2 | 150-3500 | 6204 6205 |

| 102 | 4 | 150-3500 | 6204 6205 6305 |

| 108 | 4 1/4 | 150-3500 | 6204 6205 6305 6306 |

| 114 | 4 1/2 | 150-3500 | 6204 6205 6305 6306 |

| 127 | 5 | 150-3500 | 6204 6205 6305 6306 |

| 133 | 5 1/4 | 150-3500 | 6205 6206 6207 6305 6306 |

| 140 | 5 1/2 | 150-3500 | 6205 6206 6207 6305 6306 |

| 152 | 6 | 150-3500 | 6205 6206 6207 6305 6306 6307 6308 |

| 159 | 6 1/4 | 150-3500 | 6205 6206 6207 6305 6306 6307 6308 |

| 165 | 6 1/2 | 150-3500 | 6207 6305 6306 6307 6308 |

| 177.8 | 7 | 150-3500 | 6207 6306 6307 6308 6309 |

| 190.5 | 7 1/2 | 150-3500 | 6207 6306 6307 6308 6309 |

| 194 | 7 5/8 | 150-3500 | 6207 6307 6308 6309 6310 |

| 219 | 8 5/8 | 150-3500 | 6308 6309 6310 |

| Macluumaadka aasaasiga ah. | |

| Qaabka NO. | NS/RS/LS |

| Dhamaystirka dusha sare | Rinjiyeynta, Galvanized ama sida Dalabkaaga |

| Dhererka | 200-2800mm |

| Midabka | sida looga baahan yahay |

| Soodejinta Xamuulka | Lyc (China Caanka ah) NSK, SKF |

| Heerka | ISO, Cema, DIN |

| Shahaado | ISO9001:2015 |

| Dhisme | Gawaarida Qaadista |

| Dhexroorka Iidler | 89,108,133,159,194,219mm |

| Midabka | Sida Codsigaaga |

| Astaamaha | Waara, Keyd Awoodeed, iwm. |

| Tilmaamaha Qalabka | Waara |

| Adeegga Iibka Kadib | Injineerada laga heli karo Mashiinnada Adeegga ee Dibadda |

| Awoodda Xamuulka | Sida Dalkuba yahay |

| Faahfaahinta Baakadaha | Kiis alwaax ah, Baakadaha suufka, Baakaynta caadiga ah |

| Astaanta ganacsiga | GCS, GCS |

| Xidhmada Gaadiidka | Sanduuqa alwaaxa |

| Tilmaamid | Shuruudaha Macaamiisha |

| Asal ahaan | Guangdong, Shiinaha (Dhul-weynaha) |

| Koodhka HS | 8431390000 |

Codsiga Roller Idler

GCS Conveyor Roller-ka alaabada waxaa si weyn loogu isticmaalaa soosaarka tamarta kulaylka, dekedaha, dhirta sibidhka, biraha, iyo sidoo kale agabka gudbinta iftiinka ee warshadaha.

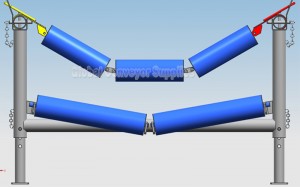

Gaadhi rullaluistemadka V

Wariyaha Macdanta

Video

suunka wareejinta Roller Idler

Rolalaha hordhaca ah ee qaadaha

Alaabta la xidhiidha

Wixii ku saabsan rollers-ka, waxaan samayn karnaa rollers-kumbuyuutarrada cuf-isjiidadka, rollers-ka birta ah, rollers-ka wadista, rullalulayaasha xamuulka dhexe ee khafiifka ah, rollers-ka-suunka duuban, rollers-ka cuf-jiidad, rollers-polymer sprocket, iyo wixii la mid ah. Faahfaahin dheeraad ah, fadlan nala soo xiriir.

cabsi. Alaabadayada waxaa loo iibiyaa aduunka waxayna ka helaan sumcad sare macaamiisheena. 1) Naqshad adag, oo ku habboon qaadista culus. 2) Guryaha xadhkaha iyo tuubada birta ah ayaa la isku ururiyaa oo lagu alxanayaa si toos ah. 3) Goynta tuubada birta iyo xajinta waxaa lagu sameeyaa iyadoo la adeegsanayo qalab / mashiinka / qalabka dhijitaalka ah. 5) Samaynta rullaluistu waxaa lagu sameeyaa qalab auto waxaana 100% la tijaabiyey in uu xooga saarayo.