Soo celinta saxanka caagga ah Idler - Shiinaha GCS alaab-qeybiye rullaluistuyaal ah

QAAB:

Balaadhka suunka: 400-2800mm

Daaweynta Dusha sare: Dahaarka budada Electrostatic, Galvanization.

Heerka: DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR iwm.

CODSIGA

Macdanta|Meelka birta|Warshada Sibidhka|Warshada Korontada

Kaydinta|iwm.

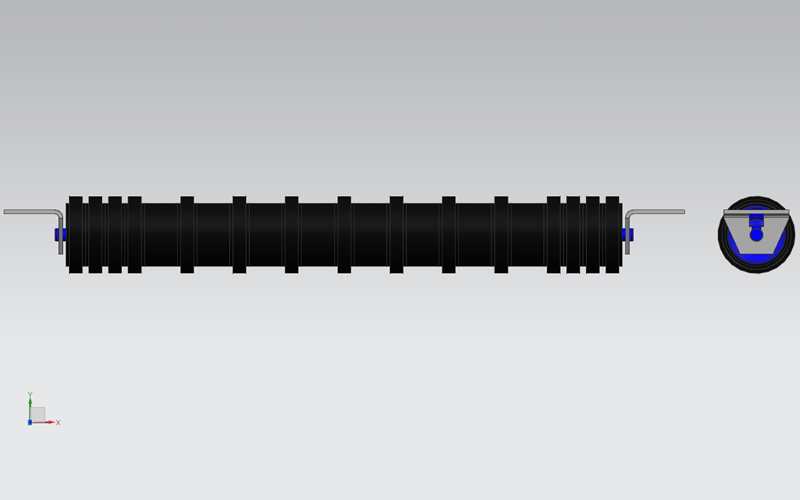

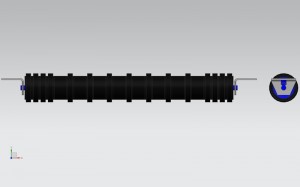

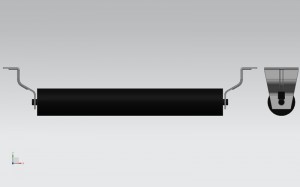

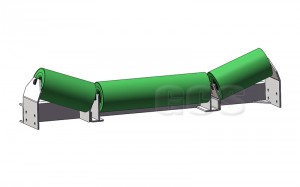

Soo laabashada saxanka caagga ah Idler - TAXANAHA RS-HRS

RUBBER DISC OO KU SOO NOQDAY IDLER OO LEH BAX-127 Dhexroor

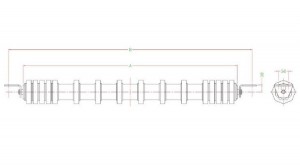

| Koodhka No. | A | B | Dhamaadka saxanka | Saxanka dhexe | Shaft Dia. | Tirada RP | Wadarta guud |

| XX-G1-1-K0E2-0500-YY | 575 | 750 | 8 | 2 | 27 | 7.8 | 13.1 |

| XX-G1-1-K0E2-0600-YY | 675 | 850 | 10 | 3 | 27 | 9.6 | 15.3 |

| XX-G1-1-K0E2-0650-YY | 725 | 900 | 10 | 3 | 27 | 10.0 | 15.9 |

| XX-G1-1-K0E2-0750-YY | 825 | 1000 | 10 | 4 | 27 | 11.0 | 16.4 |

| XX-G1-1-K0E2-0800-YY | 875 | 1150 | 10 | 4 | 27 | 11.4 | 18.1 |

| XX-G1-1-K0E2-0900-YY | 975 | 1050 | 10 | 5 | 27 | 12.5 | 19.6 |

| XX-G1-1-K0E2-1000-YY | 1075 | 1250 | 10 | 6 | 27 | 13.6 | 21.0 |

| XX-G1-1-K0E2-1050-YY | 1125 | 1300 | 10 | 6 | 30 | 14.0 | 23.1 |

| XX-G1-1-K0E2-1200-YY | 1275 | 1450 | 10 | 7 | 30 | 15.4 | 25.2 |

| XX-G1-1-K0E3-1350-YY | 1425 | 1650 | 10 | 9 | 33 | 17.3 | 30.0 |

| XX-G1-1-K0E3-1400-YY | 1475 | 1700 | 10 | 9 | 33 | 17.7 | 30.7 |

XX-ku-gelinta: RS ama HRS.

Si aad u hesho meel kale oo ka mid ah hoos u dhigista dhererka tixraac nidaamka aqoonsiga.

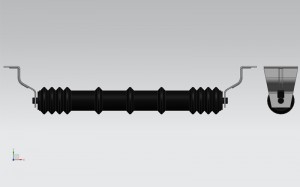

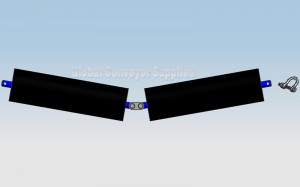

RUBBER DISC KU SOO NOQOSHAHA IDLER OO LEH MAGAALADA-152178 Dhexroor

| Koodhka No. | A | B | Dhamaadka saxanka | Saxanka dhexe | Taxanaha 45aad | Taxanaha 50aad | ||||

| Shaft Dia. | Tirada RP | Wadarta guud | Shaft Dia. | Tirada RP | Wadarta guud | |||||

| XX-G1-1-K0E2-0600-YY | 675 | 850 | 6 | 2 | 38 | 13.8 | 24.2 | 38 | 15.4 | 25.8 |

| XX-G1-1-K0E2-0650-YY | 725 | 900 | 6 | 2 | 38 | 14.9 | 26.6 | 38 | 16.5 | 28.2 |

| XX-G1-1-K0E2-0750-YY | 825 | 1000 | 6 | 3 | 38 | 16.3 | 28.9 | 38 | 18.1 | 30.7 |

| XX-G1-1-K0E2-0800-YY | 875 | 1050 | 6 | 3 | 38 | 16.9 | 30.0 | 38 | 18.7 | 31.8 |

| XX-G1-1-K0E2-0900-YY | 975 | 1150 | 6 | 3 | 38 | 18.0 | 32.0 | 38 | 19.8 | 33.8 |

| XX-G1-1-K0E2-1000-YY | 1075 | 1250 | 6 | 4 | 38 | 19.9 | 34.7 | 38 | 21.9 | 36.7 |

| XX-G1-1-K0E2-1050-YY | 1125 | 1300 | 6 | 4 | 38 | 20.4 | 35.7 | 38 | 22.4 | 37.7 |

| XX-G1-1-K0E2-1200-YY | 1275 | 1450 | 6 | 5 | 38 | 22.9 | 39.5 | 38 | 25.1 | 41.7 |

| XX-G1-1-K0E3-1350-YY | 1425 | 1650 | 6 | 7 | 38 | 26.7 | 45.1 | 38 | 29.3 | 47.7 |

| XX-G1-1-K0E3-1400-YY | 1475 | 1700 | 6 | 7 | 38 | 27.3 | 46.6 | 38 | 29.9 | 49.2 |

| XX-G1-1-K0E3-1500-YY | 1575 | 1800 | 8 | 6 | 38 | 29.1 | 48.9 | 38 | 31.9 | 51.7 |

XX-ku-galka: RS ama HRS.

Soosaarayaasha rullaluleyda GCSwaxay xaq u leedahay inay beddesho cabbirada iyo xogta muhiimka ah wakhti kasta iyada oo aan wax ogeysiin ah laga helin. Macaamiishu waa in ay hubiyaan in ay GCS ka helaan sawiro shahaadaysan ka hor inta aan la dhamaystirin faahfaahinta naqshadaynta.

1.Waa maxay rollers-ka caagga ah ee loo isticmaalo?

Isticmaalka aasaasiga ah ee rookaha caagga ah waxaa laga helaa hababka wax soo saarka ee dunta, filimada, xaashida, waraaqaha iyo birta duuban. Roollada daboolan ee caagga ah waxaa loo isticmaalaa dhammaan noocyada weel iyo baakadaha qalabka wax lagu sameeyo iyo sidoo kale mashiinnada loo isticmaalo shiididda iyo shiididda alwaax, birta iyo aluminiumka.

2.Sidee loo sameeyaa rollers-ka caagga ah?

Rollers-ka caagga ah waxaa sida caadiga ah lagu soo saaraa wax ka shubidda ama qaabeynta, laakiin sidoo kale waxaa laga yaabaa in lagu sameeyo extrusion. Hababka tuurista waxa kaliya oo loo adeegsadaa rolalka caagga ah ee leh biraha birta ah. Xaaladdan oo kale, koofiyadaha waxaa lagu sameeyaa habka shubista birta sida shaambada, ka dib markaa waxay ku xiran yihiin daahan caag ah.