Caag-ka-caageedka Vee Soo-celinta Idler ee alaab-qeybiyeyaasha GCS | GCS

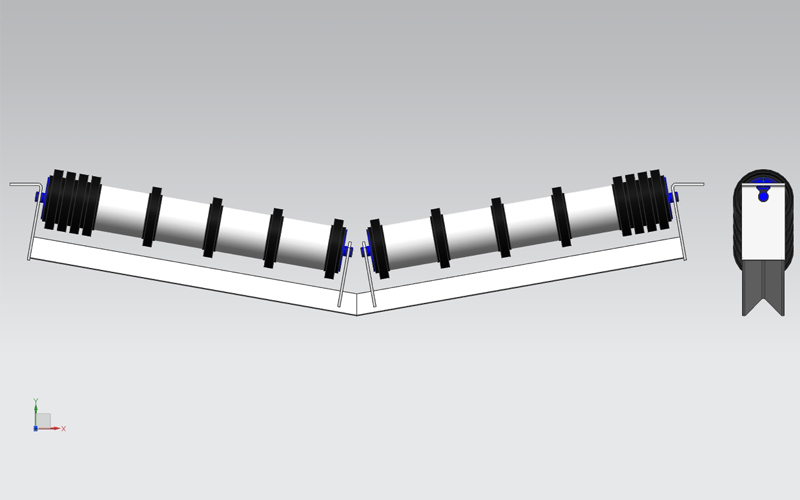

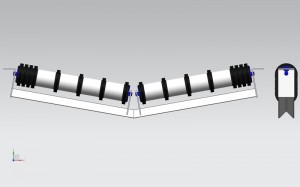

GaadhidaSoo-saare Soo-noqoshada Idler- V soo celinta saxanka caagga ah, Soo-celinta Idler oo ay bixiso GCSsoo saarayaasha rullaluistemadka shiinaha

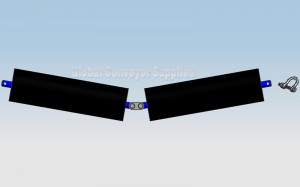

Ujeedada isticmaalka dib-u-celinta fidsan waa in laga taageero suunka dhinaca soo laabashada si looga hortago fiditaanka, hoos u dhaca, iyo fashilka suunka, taas oo kordhisa nolosha adeeggasuunka qaada.

GCS'S vee soo celinta fareemooyinka shaqo la'aanta waa la farsameeyay oo la sameeyay si ay uga sarreeyaan heerarka warshadaha iyo/ama qeexida macaamiisha.Farsamooyinka wax soo saarkawaxaa ka mid ah CNC laser-cutters iyo alxanka robotic. Isku darka qalabka wax soo saarka ee tiknoolajiyada sare, iyo maareynta alxanka / hababka hubinta ayaa hubinaya dhammaansoo noqo shaqo la'aanlooxyada waxay dejiyaan halbeeg loogu talagalay dulqaadka iyo heerarka tayada.

Tilmaamaha bandwidth (mm) 900-3000

Tilmaamaha dhexroorka tuubada (mm) 127 | 152 | 178

Idler soo celinta caagga - TAXANAHA RS/HRS

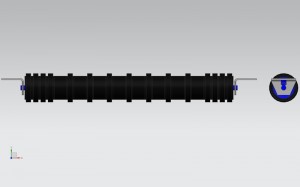

RUBBER DISC VEE SOO NOQO IDLER-LA'AAN BAX 178 dhexroor

| Koodhka No. | A | B | 5 | 10° | 15° | Qty. Dhamaadka saxanka | Qty. Saxanka dhexe | Xagalka Saldhigga | Shaft Dia. | Tirada RP | Wadarta guud | ||||||

| C | D | F | C | D | F | C | D | F | |||||||||

| XX-G1-2-C0K2-1200-YY | 625 | 1450 | 57 | 1305 | 7 | 112 | 1262 | 63 | 166 | 1232 | 119 | 3 | 4 | 75 | 38 | 32.7 | 56.5 |

| XX-G1-2-C0K3-1350-YY | 700 | 1650 | 63 | 1455 | 15 | 125 | 1412 | 76 | 186 | 1384 | 139 | 3 | 4 | 75 | 38 | 35.3 | 62.2 |

| XX-G1-2-C0K3-1400-YY | 725 | 1700 | 65 | 1505 | 18 | 129 | 1462 | 80 | 193 | 1434 | 146 | 3 | 4 | 75 | 38 | 36.2 | 64.2 |

| XX-G1-2-C0K3-1500-YY | 775 | 1800 | 69 | 1605 | 22 | 139 | 1562 | 90 | 207 | 1534 | 160 | 4 | 4 | 75 | 38 | 39.3 | 68.7 |

| XX-G1-2-C0K5-1600-YY | 825 | 2000 | 76 | 1755kii | 33 | 148 | 1664 | 99 | 220 | 1638 | 173 | 4 | 5 | 75 | 38 | 42.7 | 75.2 |

| XX-G1-2-D0K5-1800-YY | 925 | 2200 | 85 | 1955kii | 42 | 164 | 1864kii | 115 | 247 | 1838kii | 200 | 4 | 6 | 90 | 38 | 47.9 | 86.6 |

| XX-G1-2-E0K5-2000-YY | 1025 | 2400 | 93 | 2155 | 50 | 182 | 2064 | 133 | 274 | 2038 | 227 | 4 | 6 | 100 | 38 | 51.3 | 102.1 |

| XX-G1-2-F0K5-2200-YY | 1125 | 2600 | 102 | 2355 | 59 | 200 | 2264 | 151 | 302 | 2238 | 255 | 4 | 7 | 125 | 38 | 56.5 | 120.4 |

| XX-G1-2-F0K5-2400-YY | 1225 | 2800 | 111 | 2555 | 68 | 218 | 2464 | 169 | 330 | 2438 | 283 | 4 | 7 | 125 | 38 | 59.9 | 128.7 |

| XX-G1-2-F0K5-2500-YY | 1275 | 2900 | 116 | 2655 | 73 | 227 | 2564 | 178 | 344 | 2538 | 297 | 4 | 7 | 125 | 38 | 61.7 | 133.0 |

| XX-G1-2-G0K5-2600-YY | 1325 | 3000 | 120 | 2755 | 77 | 236 | 2664 | 187 | 358 | 2638 | 311 | 4 | 8 | 140 | 38 | 65.1 | 158.3 |

| XX-G1-2-G0K5-2800-YY | 1425 | 3200 | 129 | 2955 | 86 | 254 | 2864 | 205 | 386 | 2838 | 339 | 4 | 8 | 140 | 38 | 68.6 | 168.0 |

| XX-G1-2-G0K5-3000-YY | 1525 | 3400 | 138 | 3155 | 95 | 272 | 3064 | 223 | 414 | 3038 | 367 | 4 | 9 | 140 | 38 | 74.7 | 180.3 |

Fiiro gaar ah:XX-gelinta: RS ama HRS.

YY-Inputforangle: 5°, 10°, 15°

Cabbirka xagasha saldhiga ee la magacaabay waa heerka caadiga ah ee saamiyada. Cabbirrada G way ku kala duwanaan doonaan isbeddelka cabbirka xagasha.

| Xagasha saldhiga | G |

| 63 x 63 x 5L | 253 |

| 75x75x6L | 263 |

| 90x90x7L | 273 |

| 100x100x8L | 283 |

| 125x125x8L | 303 |

| 140x140x12L | 323 |

GCS waxay xaq u leedahay inay beddesho cabbirada iyo xogta muhiimka ah wakhti kasta ogeysiis la'aan. Macaamiishu waa in ay hubiyaan in ay GCS ka helaan sawiro shahaadaysan ka hor inta aan la dhamaystirin faahfaahinta naqshadaynta.