GCS Conveyor Solution New Birta Qaadaya Rollers

GAADHI SALAAR AH| SOO CELIN IDLAYAAL

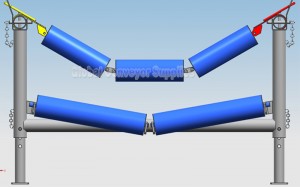

Iyada oo qayb ka ah (GCS)AALADAHA GUDBINTA CAALAMKAtiro balaadhan oo ah shirarka aan shaqayn ee ku habboon inta badancodsiyada gudbinta- lagu farsameeyay si waafaqsan heerarka warshadaha ugu sarreeya.

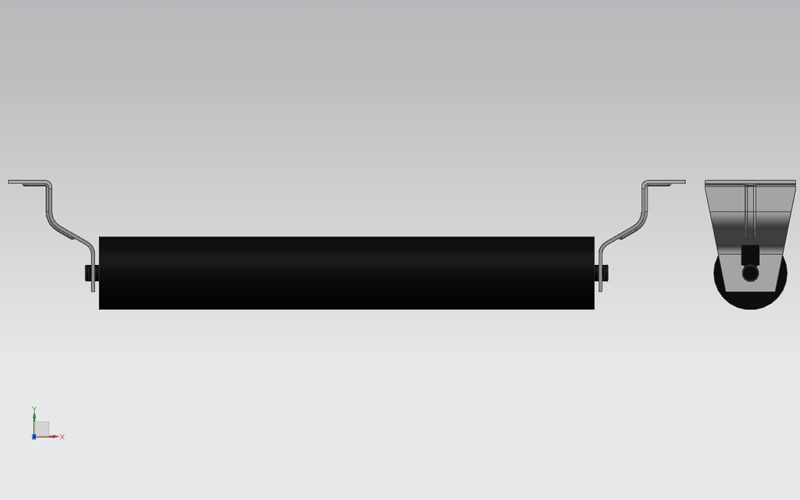

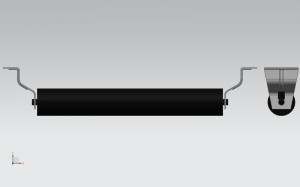

(GCS)AALADAHA GUDBINTA CAALAMKADib u soo celinta Flat Idler Assemblies ayaa lagu heli karaa qaabeynta 1 ama 2-roll, iyadoo naqshadeynta 1-roll ay aad u baahsan tahay. Baaxadda suunka celinta ayaa ah culeyska kaliya ee soo laabasha shaqada looga baahan yahay inay taageeraan. Qaab-dhismeedka Idler waa la habeyn karaa si uu ugu habboonaado ballaca suunka ee loo baahan yahay. Fogaanta kuwan way ka weyn tahay ta weelka/roolaha-qaadista laakiin waa in ay ahaataa mid ku filan si looga hortago suunka qaadaha. Fogaantan inta badan waxay u dhaxaysaa 2 iyo 6 mitir.

Soo laabashada shaqo la'aanta waxaa loo isticmaalaa sidii taageerodhinaca soo laabashada suunka. Waxa loo isticmaalaa meelaha aanay alaabtu ahayn mid dhegdheg leh, daxalaysa, ama aan xoqin.

QAAB:

Balaadhka suunka: 400-2800mm

Daaweynta Dusha sare: Dahaarka budada Electrostatic, Galvanization.

CODSIGA: Macdanta|Steel Mill | Warshada Sibidhka|Warshada Korontada

SHAHAADADA: ISO9001:2015,

SHARCI GUDBINTA: GCS

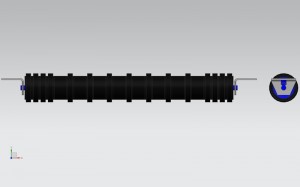

Idler soo laabasho guri -SERIES RS/HRS

SALAAXA OO SOO NOQO IDLER-152 DAMEER

| Koodhka No. | A | B | Taxanaha 20aad | Taxanaha 30aad | ||||

| Shaft Dia. | Tirada RP | Wadarta guud | Shaft Dia. | Tirada RP | Wadarta guud | |||

| XX-A1-1-K0E2-0750-YY | 849 | 1000 | 27 | 13.8 | 20.3 | N/A | N/A | N/A |

| XX-A1-1-K0E2-0800-YY | 899 | 1050 | 27 | 14.5 | 21.2 | N/A | N/A | N/A |

| XX-A1-1-K0E2-0900-YY | 999 | 1150 | 27 | 16.0 | 23.1 | N/A | N/A | N/A |

| XX-A1-1-K0E2-1000-YY | 1099 | 1250 | 27 | 17.5 | 25.0 | 33 | 17.7 | 27.8 |

| XX-A1-1-K0E2-1050-YY | 1149 | 1300 | 30 | 18.4 | 27.4 | 33 | 18.4 | 28.9 |

| XX-A1-1-K0E2-1200-YY | 1299 | 1450 | 30 | 20.4 | 30.2 | 33 | 20.6 | 32.1 |

| XX-A1-1-K0E3-1350-YY | 1499kii | 1650 | 33 | 23.4 | 36.1 | 36 | 23.6 | 38.4 |

| XX-A1 K0E3-1400-YY | 1549 | 1700 | 33 | 24.2 | 37.2 | 36 | 24.3 | 39.5 |

| XX-A1-1-K0E3-1500-YY | 1649kii | 1800 | 36 | 25.6 | 41.5 | 36 | 25.9 | 41.9 |

| XX-A1-1-K0E5-1600-YY | 1849kii | 2000 | 36 | 28.7 | 46.2 | 38 | 29.0 | 48.3 |

| XX-A1-1-K0E5-1800-YY | 2200 | N/A | N/A | N/A | 40 | 32.2 | 57.5 | |

SALAAXA OO SOO NOQO IDLER-152 DAMEER

| Koodhka No. | A | B | Taxanaha 45aad | Taxanaha 55aad | ||||

| Shaft Dia. | Tirada RP | Wadarta guud | Shaft Dia. | Tirada RP | Wadarta guud | |||

| XX-A1-1-K0E2-0900-YY | 1002 | 1150 | 38 | 16.7 | 30.7 | N/A | N/A | N/A |

| XX-A1-1-K0E2-1000-YY | 1102 | 1250 | 38 | 18.2 | 31.1 | 48 | 20.1 | 41.0 |

| XX-A1-1-K0E2-1050-YY | 1152 | 1300 | 38 | 19.0 | 34.3 | 48 | 20.8 | 42.4 |

| XX-A1-1-K0E2-1200-YY | 1302 | 1450 | 38 | 21.2 | 37.9 | 48 | 23.0 | 46.8 |

| XX-A1-1-K0E3-1350-YY | 1502 | 1650 | 42 | 24.2 | 45.7 | 48 | 25.9 | 52.5 |

| XX-A1-1-K0E3-1400-YY | 1552 | 1700 | 42 | 25.1 | 47.2 | 48 | 26.6 | 53.9 |

| XX-A1-1-K0E3-1500-YY | 1652 | 1800 | 42 | 26.6 | 49.8 | 48 | 28.1 | 56.9 |

| XX-A1-1-K0E5-1600-YY | 1852kii | 2000 | 45 | 29.9 | 58.3 | 48 | 31.0 | 62.6 |

| XX-A1-1-K0E5-1800-YY | 2052 | 2200 | 45 | 33.2 | 64.1 | 48 | 33.9 | 68.3 |

XX-ku-gelinta: RS ama HRS.

Kuwa aan shaqayn ee guriga ku raran waxay ku beddelaan E iyo H.

Si aad u beddesho dhererka hoos u dhaca soo laabashada hooyo tixraac IDE ntificati on system.

GCS waxay xaq u leedahay inay beddesho cabbirada iyo xogta muhiimka ah wakhti kasta ogeysiis la'aan. Macaamiishu waa in ay hubiyaan in ay GCS ka helaan sawiro shahaadaysan ka hor inta aan la dhamaystirin faahfaahinta naqshadaynta.

1.Sideen ku doortaa rullaayasha qaadaha?

Marka la dooranayo rollers, waxaan dooran karnaa rollers cabbirro iyo qalab kala duwan iyadoo loo eegayo xaaladaha iyo noocyada kala duwan ee alaabta. Macluumaad dheeraad ah tixraacSideen u doortaa rullaluistuliye?

2.Waa maxay conveyor iyo noociisa?

Noocyada caadiga ah waa suunka, rullaluistemadka, rullaluistuyada mootada iyo kuwa korka sareeyo.