Rubber Disc Return Idler - supplier roller conveyor GCS China

SPESIFIKASI:

Kanggo Sabuk Jembar: 400-2800mm

Perawatan lumahing: Elektrostatik Powder Coating, Galvanisasi.

Standar: DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc.

APLIKASI

Pertambangan | Pabrik baja | Pabrik Semen | Pembangkit Listrik | Pabrik Kimia | Pelabuhan Laut

Panyimpenan|dsb.

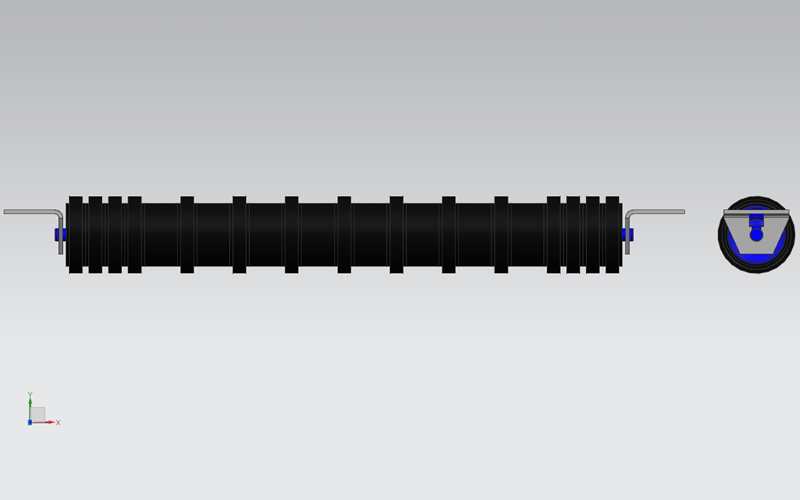

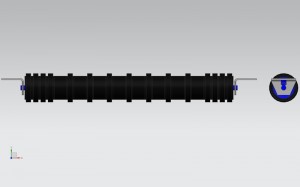

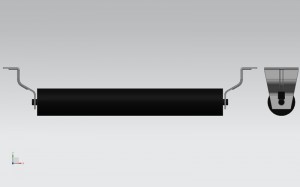

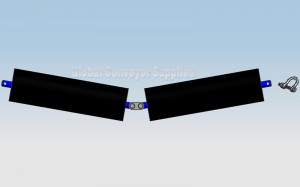

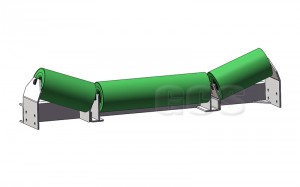

Karet Disc Return Idler - SERIES RS-HRS

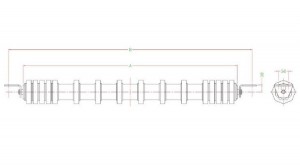

RUBBER DISC RETURN IDLER WITH SPACERS-127 Diameter

| Kode No. | A | B | Disk Pungkasan | Disc tengah | Poros Dia. | Massa RP | Total Massa |

| XX-G1-1-K0E2-0500-YY | 575 | 750 | 8 | 2 | 27 | 7.8 | 13.1 |

| XX-G1-1-K0E2-0600-YY | 675 | 850 | 10 | 3 | 27 | 9.6 | 15.3 |

| XX-G1-1-K0E2-0650-YY | 725 | 900 | 10 | 3 | 27 | 10.0 | 15.9 |

| XX-G1-1-K0E2-0750-YY | 825 | 1000 | 10 | 4 | 27 | 11.0 | 16.4 |

| XX-G1-1-K0E2-0800-YY | 875 | 1150 | 10 | 4 | 27 | 11.4 | 18.1 |

| XX-G1-1-K0E2-0900-YY | 975 | 1050 | 10 | 5 | 27 | 12.5 | 19.6 |

| XX-G1-1-K0E2-1000-YY | 1075 | 1250 | 10 | 6 | 27 | 13.6 | 21.0 |

| XX-G1-1-K0E2-1050-YY | 1125 | 1300 | 10 | 6 | 30 | 14.0 | 23.1 |

| XX-G1-1-K0E2-1200-YY | 1275 | 1450 | 10 | 7 | 30 | 15.4 | 25.2 |

| XX-G1-1-K0E3-1350-YY | 1425 | 1650 | 10 | 9 | 33 | 17.3 | 30.0 |

| XX-G1-1-K0E3-1400-YY | 1475 | 1700 | 10 | 9 | 33 | 17.7 | 30.7 |

XX-input kanggo: RS utawa HRS.

Kanggo alternatif bali gulung dhuwur deleng sistem identifikasi.

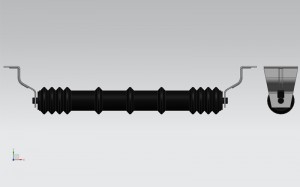

RUBBER DISC RETURN IDLER WITH SPACERS-152178 Diameter

| Kode No. | A | B | Disk Pungkasan | Disc tengah | Seri 45 | Seri 50 | ||||

| Poros Dia. | Massa RP | Total Massa | Poros Dia. | Massa RP | Total Massa | |||||

| XX-G1-1-K0E2-0600-YY | 675 | 850 | 6 | 2 | 38 | 13.8 | 24.2 | 38 | 15.4 | 25.8 |

| XX-G1-1-K0E2-0650-YY | 725 | 900 | 6 | 2 | 38 | 14.9 | 26.6 | 38 | 16.5 | 28.2 |

| XX-G1-1-K0E2-0750-YY | 825 | 1000 | 6 | 3 | 38 | 16.3 | 28.9 | 38 | 18.1 | 30.7 |

| XX-G1-1-K0E2-0800-YY | 875 | 1050 | 6 | 3 | 38 | 16.9 | 30.0 | 38 | 18.7 | 31.8 |

| XX-G1-1-K0E2-0900-YY | 975 | 1150 | 6 | 3 | 38 | 18.0 | 32.0 | 38 | 19.8 | 33.8 |

| XX-G1-1-K0E2-1000-YY | 1075 | 1250 | 6 | 4 | 38 | 19.9 | 34.7 | 38 | 21.9 | 36.7 |

| XX-G1-1-K0E2-1050-YY | 1125 | 1300 | 6 | 4 | 38 | 20.4 | 35.7 | 38 | 22.4 | 37.7 |

| XX-G1-1-K0E2-1200-YY | 1275 | 1450 | 6 | 5 | 38 | 22.9 | 39.5 | 38 | 25.1 | 41.7 |

| XX-G1-1-K0E3-1350-YY | 1425 | 1650 | 6 | 7 | 38 | 26.7 | 45.1 | 38 | 29.3 | 47.7 |

| XX-G1-1-K0E3-1400-YY | 1475 | 1700 | 6 | 7 | 38 | 27.3 | 46.6 | 38 | 29.9 | 49.2 |

| XX-G1-1-K0E3-1500-YY | 1575 | 1800 | 8 | 6 | 38 | 29.1 | 48.9 | 38 | 31.9 | 51.7 |

XX-input kanggo: RS utawa HRS.

Artikel sing gegandhengan

Produsen conveyor roller GCSnduweni hak kanggo ngganti dimensi lan data kritis sawayah-wayah tanpa kabar. Pelanggan kudu mesthekake yen dheweke nampa gambar sing disertifikasi saka GCS sadurunge ngrampungake rincian desain.

1. Apa rol karet digunakake kanggo?

Panggunaan dhasar kanggo roller karet ditemokake ing proses manufaktur tekstil, film, lembaran, kertas lan logam sing digulung. Roller ditutupi karet digunakake ing kabeh jinis wadhah lan peralatan fabrikasi kemasan uga mesin sing digunakake kanggo sanding lan grinding kayu, baja lan aluminium.

2. Carane rollers karet digawe?

Roller karet biasane diprodhuksi liwat casting utawa ngecor, nanging uga bisa digawe liwat extrusion. Proses casting digunakake mung karo rol karet sing duwe inti metalik. Ing kasus iki, intine dibentuk liwat proses casting logam kaya stamping, banjur diikat menyang lapisan karet.