Newly Arrival Rollers For Conveyors - UHMW-PE Conveyor Impact Bar – GCS

Newly Arrival Rollers For Conveyors - UHMW-PE Conveyor Impact Bar – GCS Detail:

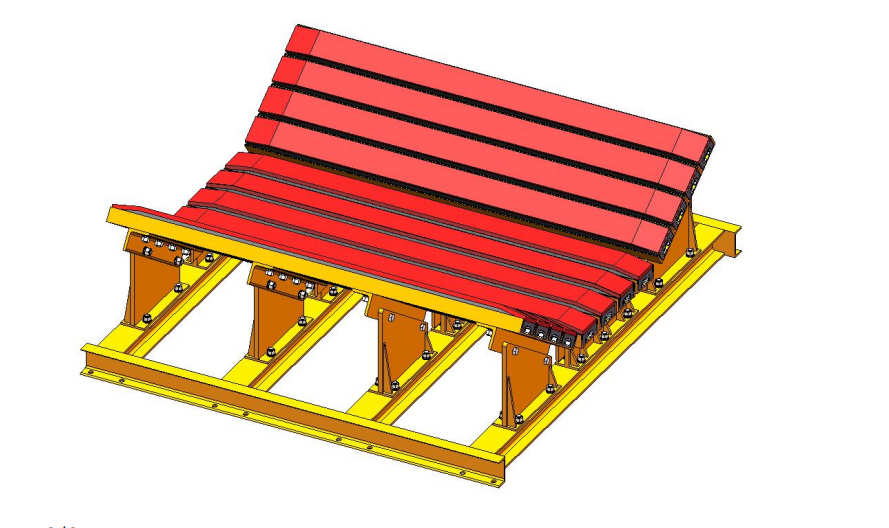

Conveyor Impact Bar

Impact bar bed

The impact bar is used to prevent damage to the belt at the loading point to maintain the stability of the belt and avoid the overflow of the material transported

Commonly used in heavy-duty conveyor loading points. The impact bar is designed to be directly below the conveyor belt.

The polyethylene top allows the belt to run on it with minimal friction, while thick rubber blocks draw energy from the material at these points.

The impact bar is made from a cast aluminum T-groove base covered with a 60 Shore hard rubber solid block topped with 10 mm polyethylene.

GCS offers M16 x 40mm forged T-bolts as standard. Longer bolts are available upon request.

Conveyor Impact Bar characteristics

1. Ultra-low friction coefficient

2. Ultra-high wear resistance of surface wear-resistant layer,

3. No damage to the conveyor belt

4. Effectively prevent material splashing

5. Good shock absorption effect

6. Product integrity is strong, no moving parts

7. Convenient replacement, improve work efficiency

8. The friction on the conveyor belt is very low and uniform, extending the service life of the conveyor belt

9. Aluminum profiles are not easy to rust when exposed to water

10. Site installation and maintenance is simple, the left and right side beds can be removed as a whole, to facilitate the side sliding into the installation by the conveyor

11. The support part of the buffer press is designed and welded according to the requirements of on-site mining and installation and maintenance. Its structure is durable, has simple installation, convenient maintenance, and reduces the potential safety hazards and procurement costs brought by frequent maintenance.

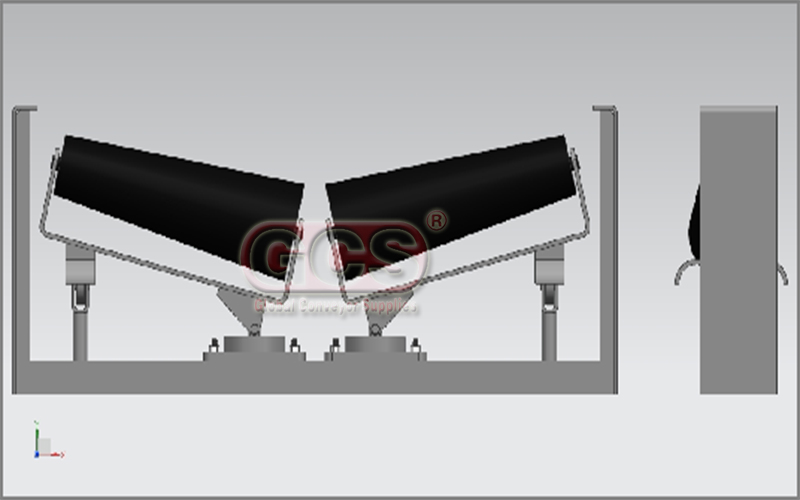

Drawing of Conveyor Impact Bar

Specification of UHMW-PE Conveyor Impact Bar

| Corresponding NO | A | E | L1 | L2 | Ch | P | N | UHMW-PE panels |

| RKM-HCC-80*122 | 1090 | 1140 | 1220 | 315 | 180 | 120 | 200 | 6 |

| RKM-HCC-100*122 | 1290 | 1340 | 1220 | 380 | 213 | 120 | 200 | 9 |

| RKM-HCC-120*122 | 1540 | 1582 | 1220 | 465 | 230 | 120 | 200 | 9 |

| RKM-HCC-140*140 | 1740 | 1782 | 1400 | 530 | 238 | 120 | 360 | 12 |

| RKM-HCC-160*140 | 1990 | 2032 | 1400 | 600 | 282 | 120 | 360 | 12 |

| RKM-HCC-180*160 | 2190 | 2232 | 1600 | 670 | 295 | 120 | 360 | 15 |

Conveyor Impact Bar video

Related product

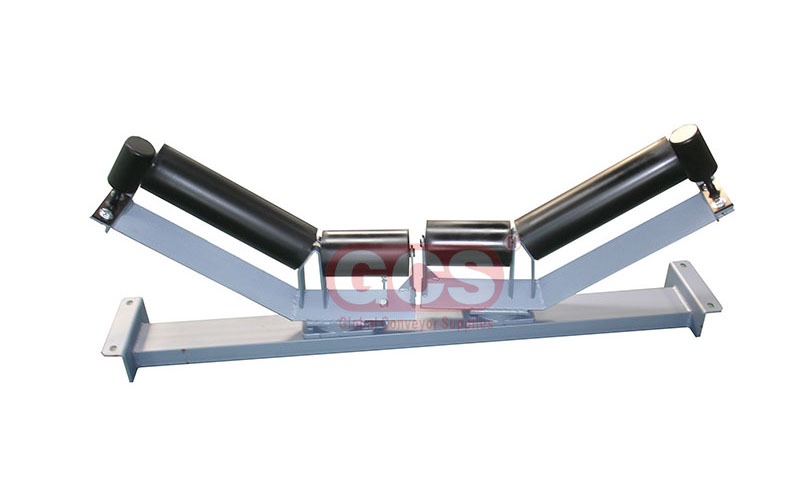

Trough impact roller is applied in the mine

Conveyor Roller Manufacturers Of Rubber Disc Return Idler

Rubber Disc Vee Return Idler by GCS Suppliers

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

Tell Us Your Requirement About Trough Idler .Contact us Now!

Product detail pictures:

Related Product Guide:

We believe that long term partnership is a result of high quality, value added service, rich experience and personal contact for Newly Arrival Rollers For Conveyors - UHMW-PE Conveyor Impact Bar – GCS , The product will supply to all over the world, such as: Houston, Seattle, Slovakia, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We have been ready to face the worries and make the improve to understand all the possibilities in international trade.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.