High Performance Rollers For Conveyor Systems - Conveyor Impact Roller Manufacturers | GCS – GCS

High Performance Rollers For Conveyor Systems - Conveyor Impact Roller Manufacturers | GCS – GCS Detail:

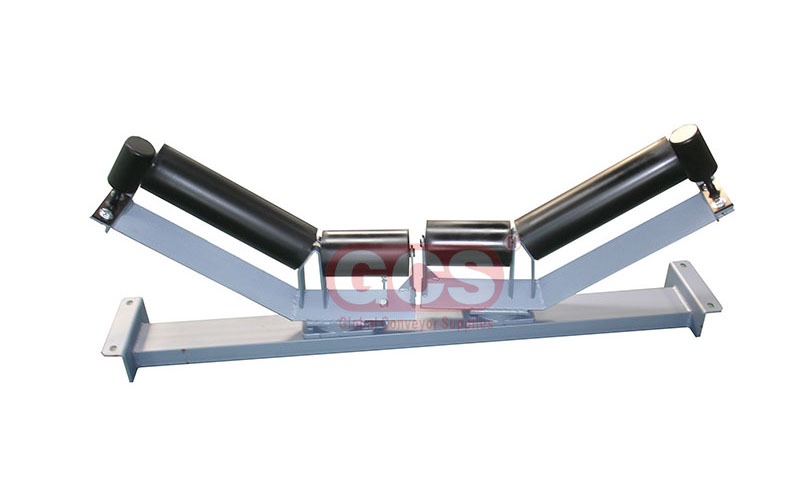

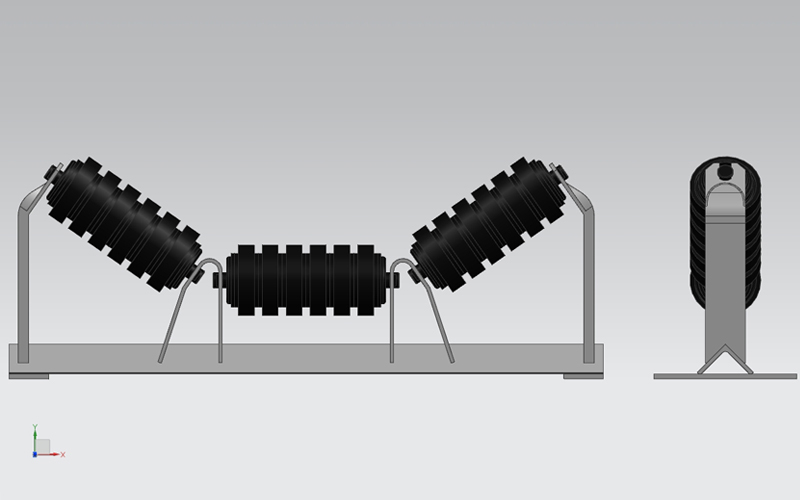

lmpact rollers set

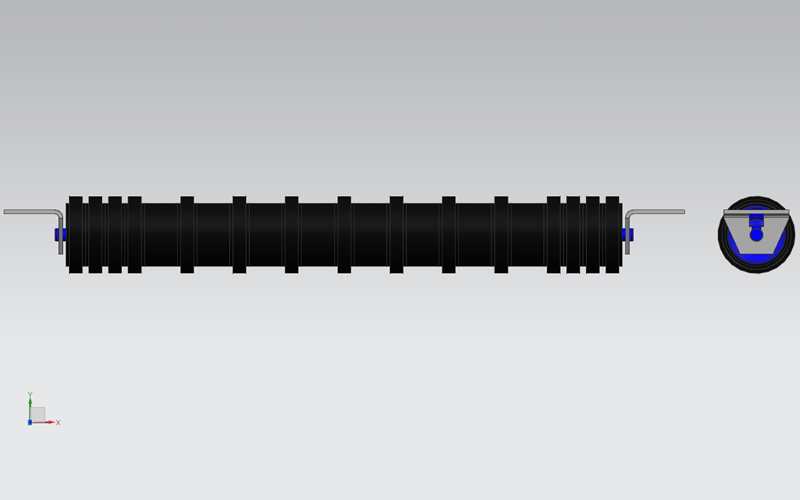

lmpact rollers are used and positioned corresponding to the load points, where the lumps and the weight of material fling onto the belt could in fact cause damage to it.To limit the impact effect of the material onto the rollers, the atter are covered with a series of rubber rings of adequate thickness and resistance.

Impact rollers are under stress not only from the load of the material, but also from the dynamic forces as the loadalls onto the belt. The impact onto the belt, arising from the free fall of material will be naturally greater than in the case where the material is deflected onto the belt by an inclined.

For the correct dimension and the choice of impact rollers in relation to the load check the characteristics of the base roller.

Material Iron

Application Chemical Industry| Grain Transportation|Mining Transport|Power

Plant|Structure Ordinary Roller|Bearing Type|Double Sealed Bearing

Type:Impact Idler

Product Name:Impact Idler Roller

Usage:Conveyor Belt System

Diameter:50-219 mm

Surface Preparation:Spray Paint

Color:Requirements

Certification:ISO 9001 : 2015

Trademark: GCS

HS Code:8431390000

Trough Idler -SERIES RS/HRS

3 ROLL TROUGH IDLERS-152 DIAMETER

| Code No. | A | B | 20° | 30° | 35° | 45° | Base Angle Size | Shaft Dia. | Trough Mass | Total | Shaft Dia. | Impact Mass R.P. | Total Mass | ||||

| C | D | C | D | C | D | C | D | R.P. | Mass | ||||||||

| XX-A1-3-C2A2-0750-YY | 283 | 1000 | 106 | 856 | 144 | 818 | 164 | 782 | 194 | 694 | 75 | 27 | 17.6 | 35.2 | 38 | 23.7 | 46.2 |

| XX-A1-3-C2A2-0800-YY | 299 | 1050 | 106 | 892 | 159 | 860 | 179 | 818 | 206 | 736 | 75 | 27 | 18.1 | 36.4 | 38 | 24.8 | 48.5 |

| XX-A1-3-C2A2-0900-YY | 336 | 1150 | 117 | 1016 | 175 | 962 | 196 | 922 | 235 | 818 | 75 | 27 | 19.2 | 38.8 | 38 | 24.7 | 53.1 |

| XX-A1-3-C2A2-1000-YY | 363 | 1250 | 127 | 1092 | 188 | 1038 | 215 | 988 | 256 | 882 | 75 | 27 | 20.3 | 41.2 | 38 | 27.2 | 57.7 |

| XX-A1-3-C2A2-1050-YY | 388 | 1300 | 142 | 1162 | 204 | 1104 | 226 | 1058 | 270 | 946 | 75 | 27 | 21.4 | 43.1 | 38 | 28.5 | 60.4 |

| XX-A1-3-C2A2-1200-YY | 441 | 1450 | 157 | 1314 | 224 | 1252 | 260 | 1192 | 311 | 1068 | 75 | 27 | 23.8 | 47.5 | 38 | 32.4 | 67.6 |

| XX-A1-3-D2A3-1350-YY | 493 | 1650 | 177 | 1462 | 255 | 1392 | 283 | 1338 | 346 | 1196 | 90 | 30 | 26.0 | 55.0 | 38 | 35.2 | 76.6 |

| XX-A1-3-D2A3-1400-YY | 499 | 1700 | 177 | 1484 | 255 | 1414 | 295 | 1342 | 346 | 1224 | 90 | 30 | 26.3 | 56.6 | 38 | 35.7 | 77.7 |

| XX-A1-3-E2A3-1500-YY | 546 | 1800 | 192 | 1618 | 287 | 1530 | 316 | 1474 | 389 | 1312 | 100 | 30 | 28.4 | 67.1 | 38 | 39.1 | 91.9 |

| XX-A1-3-E2A5-1600-YY | 566 | 2000 | 192 | 1680 | 287 | 1592 | 334 | 1518 | 389 | 1390 | 100 | 33 | 29.2 | 72.5 | 38 | 39.9 | 95.9 |

Note: XX-input for: RS or HRS.

YY-Input for angle: 20°, 30°, 35°,45°

Base angle size nominated is normal stock standard. Dimensions E and F vary with change in base angle size as tabulated below.

Code numbers shown are for plain trough idlers, for impact idlers change both” A’s” in code numbers to ” B’s

SERIES RS/HRS 3 ROLL TROUGH IDLERS-152 DIAMETER

| Code No. | A | B | 20° | 30° | 35° | 45° | Base Angle Size | Shaft Dia. | Trough Mass R.P. | Total Mass | Shaft Dia. | Impact Mass R.P. | Total Mass | ||||

| C | D | C | D | C | D | C | D | ||||||||||

| XX-A1-3-C2A2-1000-YY | 363 | 1250 | 127 | 1092 | 188 | 1038 | 215 | 988 | 256 | 882 | 75 | 27 | 21.1 | 42.2 | 38 | 27.2 | 57.9 |

| XX-A1-3-C2A2-1050-YY | 388 | 1300 | 142 | 1162 | 204 | 1104 | 226 | 1058 | 270 | 946 | 75 | 27 | 22.2 | 44.1 | 38 | 28.5 | 60.6 |

| XX-A1-3-D2A2-1200-YY | 441 | 1450 | 157 | 1314 | 224 | 1252 | 260 | 1192 | 311 | 1068 | 90 | 27 | 24.5 | 50.5 | 38 | 32.4 | 70.4 |

| XX-A1-3-D2A3-1350-YY | 493 | 1650 | 177 | 1462 | 255 | 1392 | 283 | 1338 | 346 | 1196 | 90 | 30 | 26.8 | 56.6 | 38 | 35.2 | 76.8 |

| XX-A1-3-D2A3-1400-YY | 499 | 1700 | 177 | 1484 | 255 | 1414 | 295 | 1342 | 346 | 1224 | 90 | 30 | 27.0 | 57.6 | 38 | 35.7 | 78.0 |

| XX-A1-3-E2A3-1500-YY | 546 | 1800 | 192 | 1618 | 287 | 1530 | 316 | 1474 | 389 | 1312 | 100 | 30 | 29.1 | 68.1 | 38 | 39.1 | 92.2 |

| XX-A1-3-F2A5-1600-YY | 566 | 2000 | 192 | 1680 | 287 | 1592 | 334 | 1518 | 389 | 1390 | 125 | 33 | 30.0 | 80.5 | 38 | 39.9 | 105.7 |

| XX-A1-3-F2A5-1800-YY | 630 | 2200 | 222 | 1856 | 323 | 1760 | 369 | 1688 | 436 | 1544 | 125 | 33 | 32.8 | 88.0 | 38 | 44.8 | 117.1 |

Note: XX-inputfor: RS or HRS.

YY-Input for angle: 20°, 30°,35°,45°

Base angle size nominated is normal stock standard. Dimensions E and F do not vary with change in base angle size as tabulated below.

Code numbers shown are for plain trough idlers, for impact idlers change both” A’sn in code numbers to ” B*s

| Base Angle | E | F |

| 75X75X6 | 165 | 235 |

| 90X90X7 | 180 | 245 |

| 100X100X8 | 200 | 255 |

| 125X125X8 | 240 | 273 |

| 140X140X12 | 280 | 292 |

Related product

Rubber Disc Return Idler

Pipe Diameter Specifications 114 mm V Return Idler

Roller For DIA(mm) 102|114|117 Flat Return Idlers

GCS conveyor roller manufacturers reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

Tell Us Your Requirement About Trough Idler .Contact us Now!

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for High Performance Rollers For Conveyor Systems - Conveyor Impact Roller Manufacturers | GCS – GCS , The product will supply to all over the world, such as: Eindhoven, San Francisco, Bangkok, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we've gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!