Self aligning conveyor roller Customized/Wholesale

Self Aligning Roller for Belt Conveyor

GCS self-aligning roller keeps your conveyor on track. This helps reduce the risk of serious belt damage.

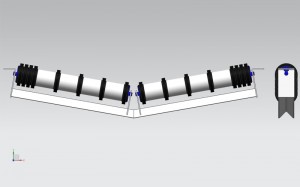

We produce 60 mm, 63.5 mm, 76 mm, 89 mm, 102 mm, 114 mm, 127 mm, 139 mm, 159 mm. They cover almost all belt width requirements. General steel rollers consist of a roller shell, spindle, bearing, bearing housing, sealing device, and axial fixing. It is recommended to install one or two sets of return centering idlers. Place them on the return side of the belt, near the tail pulley. They should be 6 to 9 meters from the pulley.

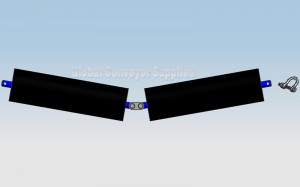

The idler side guide rollers have a concave shape to prevent the belt from running on the conveyor. To reduce belt wear, the side guide rollers are available in premium HDPE made, and are also available in plain steel Q235, reducing friction between the rollers and the belt.

How It works

The self-aligning rollers for conveyor belt use a pivoting frame or tilting structure. When the belt shifts to one side, the roller responds by rotating slightly. This small movement helps push the belt back to its proper position. There are two main types:

-

Self Aligning Carrying Roller: Positioned on the top side to support the loaded belt.

-

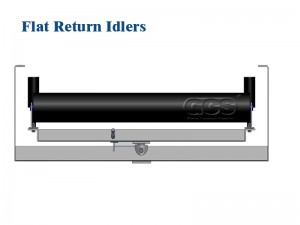

Self Aligning Return Roller: Installed underneath to support the empty return belt.

Custom Self Aligning Roller Solutions

Some conveyor systems need special designs.

At GCS, we offer custom self aligning rollers made to fit your conveyor’s size, load, and working conditions.

Whether you need different materials, sizes, or mounting options, we can help.

Detailed Return Idler Features

1. Diameter of the roller 76mm-219mm, length 190-3500mm, steel for industry, port, coal industry, power industry, cement industry, etc.

2. pipe: Q235 3. shaft: 45#Steel

4. Bearing: single-row and double-row deep groove ball bearing with C3 clearance 2RZ&2Z.

5. Seal: Multi-stage labyrinth type oil retaining inner seal and external friction retaining ring seal oil retaining cover. Special design and unique labyrinth seal form can prevent the corrosion of impurities, water, air, etc. 6.

6. Lubrication: Grease is lithium soap-type grease with an antirust agent.

7. Welding: Mixed gas-shielded arc welding end. The fine welding tube ensures the small vibration and low noise of the carrier roll.

8. Working life: 30,000-50,000 hours.

9. Standard: CEMA/JIS/DIN

Structure of Self Aligning Roller for Conveyor Belt

Applications of Self Aligning Roller for Conveyor Belt

GCS self aligning rollers for conveyor belt are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries.

Dock

Harbour

Sand&Gravel Mine

Power Plant

How to Choose the Right Self Aligning Roller for Conveyor Belt

1. Belt Width and Load

Choose a roller that matches your conveyor belt’s width and the weight of the material you’re moving.

2. Environment

For wet, dusty, or corrosive environments, select rollers made of stainless steel or with special coatings.

3. Type of Roller

Decide whether you need a carrying or return type self aligning roller—or both—for full tracking control.

4. Installation and Maintenance

Make sure the roller is easy to install and maintain. Some rollers come with sealed bearings for longer life and less upkeep.

Video

Belt Conveyor Roller Idler

Introduction conveyor roller in conveyor

Quick View Catalog