High Quality Friction Rollers - Bearing Rollers Suppliers Of the V Return Idler – GCS

High Quality Friction Rollers - Bearing Rollers Suppliers Of the V Return Idler – GCS Detail:

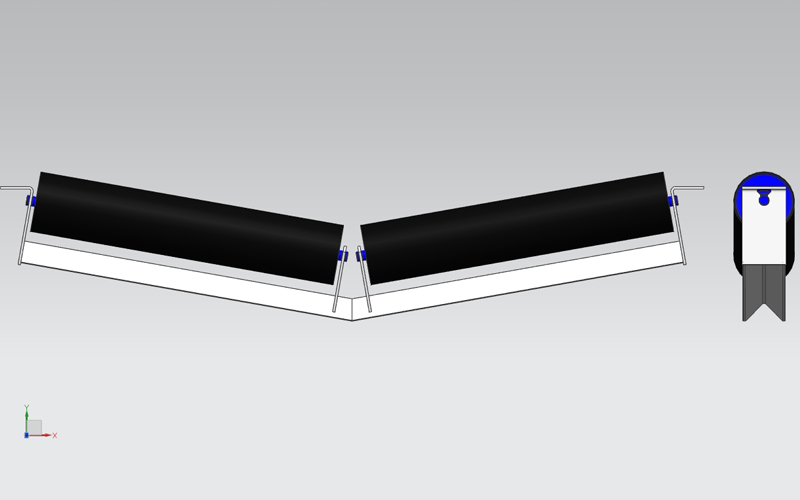

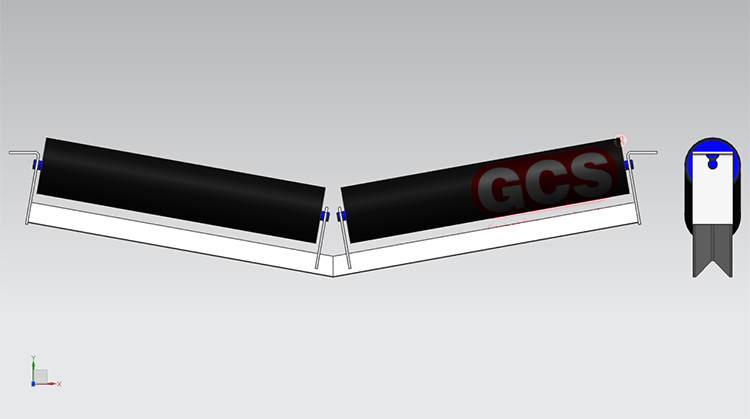

GCS’S vee return idler frames are engineered and fabricated to exceed industry standards and/or customer specifications. Manufacturing techniques include CNC laser cutters and robotic welding. The combination of high-tech manufacturing equipment, welding and our high-quality management/assurance systems ensures all vee return idler frames set a benchmark for tolerance and quality levels.

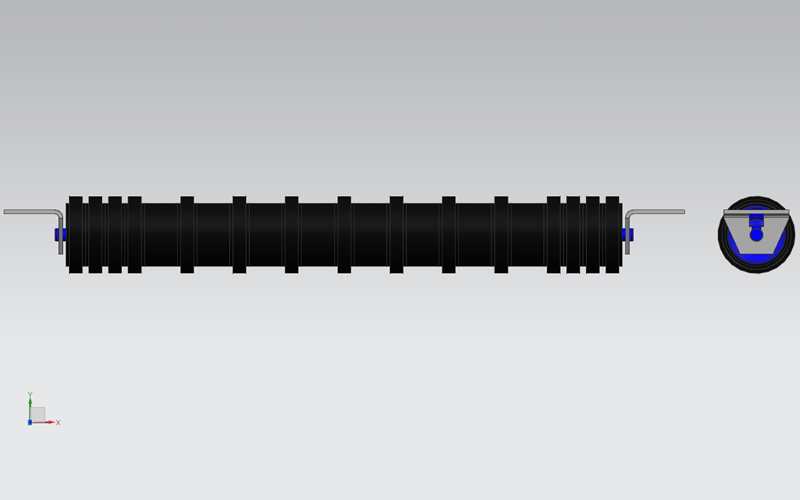

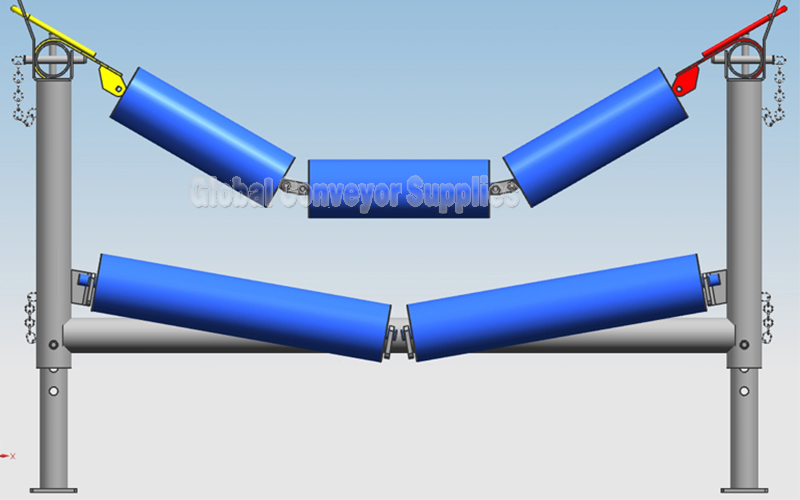

GCS’S vee return idlers are designed for use on the return side of the belt with the vee profile assisting with belt tracking. They are available with a variety of frame and mounting configurations. non-standard trough angles are available if required. Vee return idlers can house standard rollers, return rollers.

GCS’S vee return idler frames are supplied galvanised as standard, with powder-coated frames available if required. They are available to suit belt widths from 450mm up to 3000mm and can be designed and supplied to suit any belt width or roller configuration. A variety of idler frame types and sizes are held in stock. Contact us for more information.

Bandwidth specifications (mm) 900-1300

Pipe diameter specifications (mm) 800|114|127| 152 | 178

Or custom specifications

V Return Idler – SERIES RS/HRS

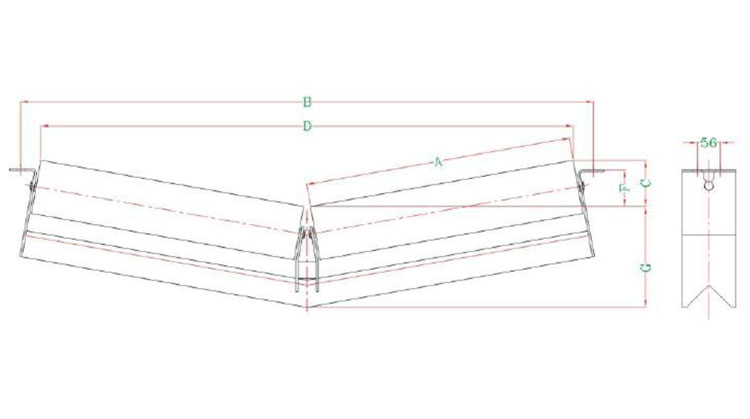

VEE RETURN IDLER-152 DIAMETER

| Code No. | A | B | 5° | 10° | 15° | Base Angle Size | Shaft Dia. | Mass R.P. | Total Mass | ||||||

| C | D | F | C | D | F | C | D | F | |||||||

| XX-A1-2-B0K2-0750-YY | 422 | 1000 | 37 | 888 | 0 | 76 | 858 | 40 | 112 | 828 | 78 | 63 | 27 | 13.4 | 23.2 |

| XX-A1-2-B0K2-0800-YY | 441 | 1050 | 40 | 938 | 3 | 81 | 908 | 45 | 119 | 878 | 85 | 63 | 27 | 14.1 | 24.4 |

| XX-A1-2-B0K2-0900-YY | 493 | 1150 | 44 | 1038 | 7 | 89 | 1008 | 53 | 132 | 978 | 98 | 63 | 27 | 15.8 | 26.9 |

| XX-A1-2-B0K2-1000-YY | 546 | 1250 | 48 | 1138 | 11 | 98 | 1108 | 62 | 145 | 1078 | 111 | 63 | 27 | 17.6 | 29.7 |

| XX-A1-2-C0K2-1050-YY | 566 | 1300 | 50 | 1188 | 13 | 103 | 1158 | 67 | 152 | 1128 | 118 | 75 | 27 | 18.0 | 33.8 |

| XX-A1-2-C0K2-1200-YY | 651 | 1450 | 57 | 1338 | 20 | 116 | 1308 | 80 | 172 | 1278 | 138 | 75 | 27 | 20.4 | 38.0 |

| XX-A1-2-C0K3-1350-YY | 750 | 1650 | 66 | 1538 | 28 | 134 | 1508 | 98 | 199 | 1478 | 165 | 75 | 27 | 24.0 | 43.9 |

| XX-A1-2-C0K3-1400-YY | 770 | 1700 | 68 | 1588 | 31 | 138 | 1558 | 102 | 206 | 1528 | 172 | 75 | 27 | 24.6 | 45.4 |

| XX-A1-2-C0K3-1500-YY | 820 | 1800 | 72 | 1688 | 35 | 148 | 1658 | 112 | 220 | 1628 | 186 | 75 | 27 | 26.2 | 47.9 |

| XX-A1-2-C0K5-1600-YY | 920 | 2000 | 83 | 1888 | 46 | 166 | 1858 | 130 | 246 | 1828 | 212 | 75 | 27 | 29.4 | 53.4 |

| XX-A1-2-D0K5-1800-YY | 1020 | 2200 | 92 | 2088 | 55 | 182 | 2058 | 146 | 273 | 2028 | 239 | 90 | 27 | 32.6 | 61.9 |

VEE RETURN IDLER-152 DIAMETER

| Code No. | A | B | 5° | 10° | 15° | Base Angle Size | Shaft Dia. | Mass R.P. | Total Mass | ||||||

| C | D | F | C | D | F | C | D | F | |||||||

| XX-A1-2-C0K2-1200-YY | 651 | 1450 | 57 | 1338 | 20 | 116 | 1308 | 80 | 172 | 1278 | 138 | 75 | 27 | 21.0 | 38.6 |

| XX-A1-2-C0K3-1350-YY | 750 | 1650 | 66 | 1538 | 28 | 134 | 1508 | 98 | 199 | 1478 | 165 | 75 | 27 | 24.2 | 44.1 |

| XX-A1-2-C0K3-1400-YY | 770 | 1700 | 68 | 1588 | 31 | 138 | 1558 | 102 | 206 | 1528 | 172 | 75 | 27 | 25.0 | 45.8 |

| XX-A1-2-C0K3-1500-YY | 820 | 1800 | 72 | 1688 | 35 | 148 | 1658 | 112 | 220 | 1628 | 186 | 75 | 27 | 26.6 | 48.3 |

| XX-A1-2-C0K5-1600-YY | 920 | 2000 | 83 | 1888 | 46 | 166 | 1858 | 130 | 246 | 1828 | 212 | 75 | 27 | 29.8 | 53.8 |

| XX-A1-2-D0K5-1800-YY | 1020 | 2200 | 92 | 2088 | 55 | 182 | 2058 | 146 | 273 | 2028 | 239 | 90 | 27 | 33.0 | 62.3 |

| XX-A1-2-E0K5-2000-YY | 1120 | 2400 | 100 | 2288 | 63 | 200 | 2258 | 164 | 300 | 2228 | 266 | 100 | 27 | 35.8 | 76.3 |

| XX-A1-2-F0K5-2200-YY | 1220 | 2600 | 109 | 2488 | 72 | 218 | 2458 | 182 | 328 | 2428 | 294 | 125 | 27 | 39.0 | 91.7 |

| XX-A1-2-F0K5-2400-YY | 1320 | 2800 | 118 | 2688 | 81 | 236 | 2658 | 200 | 356 | 2628 | 322 | 125 | 27 | 42.2 | 98.9 |

| XX-A1-2-F0K5-2500-YY | 1370 | 2900 | 123 | 2788 | 86 | 245 | 2758 | 209 | 370 | 2728 | 336 | 125 | 27 | 43.8 | 102.5 |

Note: XX-inputfor: RS or HRS.

YY-Input for angle: 20°, 30° , 35° ,45°

Base angle size nominated is normal stock standard. Dimensions E and F do not vary with change in base angle size as tabulated below.

| Base Angle | G |

| 63X63X5L | 226 |

| 75X75X6L | 236 |

| 90X90X7L | 246 |

| Base Angle | G |

| 100X100X8L | 283 |

| 125X125X8L | 303 |

| 140X140X12L | 296 |

Related product

Conveyor Roller Manufacturers Of Rubber Disc Return Idler

Trough type 45|35 degree steel roller and roller frame

Sprocket Curve Roller for conveyor drive rollers suppliers

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

Tell Us Your Requirement About Trough Idler .Contact us Now!

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We have our own factory and sourcing office. We can provide you with almost every type of product related to our product range for High Quality Friction Rollers - Bearing Rollers Suppliers Of the V Return Idler – GCS , The product will supply to all over the world, such as: Peru, Surabaya, Chile, We are your reliable partner in international markets with the best quality products. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!