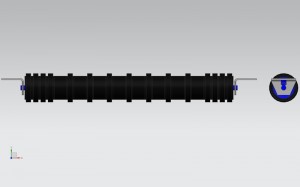

GCS Wholesale Conveyor Suppliers Trough type customized degree steel roller set with frame

GCS Conveyor Supply offers a wide range of rollers to fit most conveyor applications - designed to the highest industry standards. Roller materials, lengths, diameters, and groove options can be customized to meet customer specifications. We are a manufacturer of slotted rollers, rollers, and frames. Our factory can do it all for bulk material companies, making it simple for everyone to design and order custom rollers and affordable matching roller frames online.

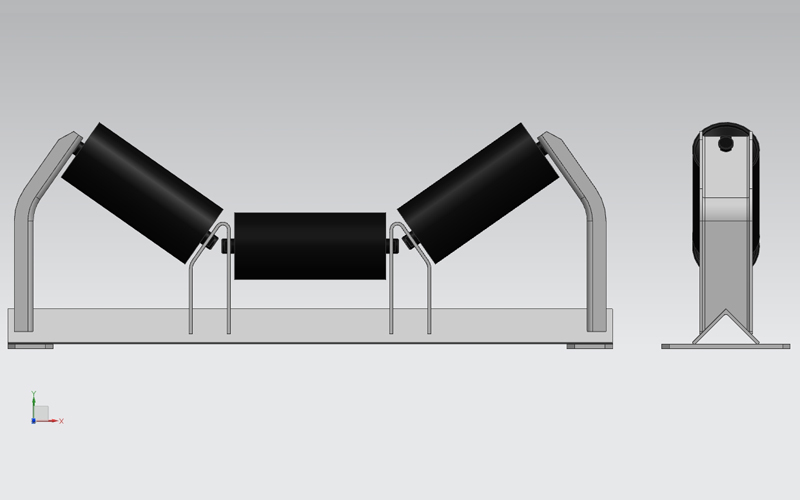

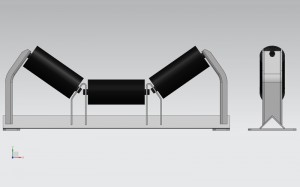

Equal Troughing Idler, a conventional carrier roller set, consists of three equal-length rollers supporting three rollers in a frame that is fixed to the conveyor structure.

Applications

Conveyor impact rollers are used for belt conveyors to receive materials and reduce and slow down the impact of the conveyor belt, mainly designed for corrosive environments such as coal washing plants, coking plants, and chemical plants. The impact rollers have good corrosion resistance and if used in corrosive situations, their service life is five times that of ordinary rollers.

Trough Idler Set

The trough idler roller set has physical and chemical properties which are high wear resistance, low friction coefficient, and not easy to wear the leather strap. It also has fine self-lubrication and is not easy to card to die in bad conditions, antistatic, flame retardant, aging resistance, and corrosion resistance. It can withstand repeated impact, and vibration, mechanical performance is excellent, lightweight, easy installation, has no maintenance, has low noise(3-7 DB), and smooth operation. The temperature of using keep in -40°C to -85°C.

The idler rollers are widely used in the original dock transporting places where dust is bigger and the environment has high corrosive, such as mining. GCS replacement conveyor rollers suppliers can make a free quotation of roller for belt conveyor, welcome to contact us!

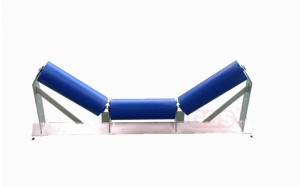

Trough Eccentric Idler - SERIES LS/RS

3 Roll Trough Idlers-offset-102 Diameter

| Code No. | A | B | 20° | 30° | 35° | 45° | E | F | Base Angle Size | Shaft Dia. | Mass R.P. | Total Mass | ||||

| C | D | C | D | C | D | C | D | |||||||||

| XX-A1-3-A1A2-0350-YY | 134 | 600 | 220 | 429 | 239 | 392 | 248 | 369 | 269 | 338 | 56 | 171 | 50 | 27 | 5.3 | 13.6 |

| XX-A1-3-A1A2-0400-YY | 152 | 650 | 226 | 477 | 248 | 443 | 256 | 418 | 281 | 380 | 56 | 171 | 50 | 27 | 5.7 | 14.4 |

| XX-A1-3-A1A2-0450-YY | 170 | 700 | 232 | 531 | 257 | 490 | 266 | 468 | 294 | 424 | 56 | 171 | 50 | 27 | 6.1 | 15.3 |

| XX-A1-3-A1A2-0500-YY | 187 | 750 | 238 | 577 | 266 | 537 | 275 | 515 | 307 | 462 | 56 | 171 | 50 | 27 | 6.4 | 16.3 |

| XX-A1-3-A1A2-0600-YY | 222 | 850 | 251 | 681 | 283 | 632 | 298 | 604 | 331 | 546 | 56 | 171 | 50 | 27 | 7.2 | 18.1 |

| XX-A1-3-A1A2-0650-YY | 242 | 900 | 259 | 741 | 295 | 691 | 311 | 657 | 345 | 602 | 56 | 171 | 50 | 27 | 7.7 | 19.1 |

| XX-A1-3-B1A2-0750-YY | 276 | 1000 | 271 | 837 | 309 | 781 | 327 | 750 | 369 | 678 | 56 | 171 | 63 | 27 | 8.4 | 21.9 |

| XX-A1-3-B1A2-0800-YY | 292 | 1050 | 274 | 883 | 320 | 821 | 339 | 789 | 380 | 718 | 56 | 171 | 63 | 27 | 8.8 | 22.9 |

| XX-A1-3-B1A2-0900-YY | 329 | 1150 | 286 | 989 | 338 | 926 | 363 | 884 | 406 | 808 | 56 | 171 | 63 | 27 | 9.6 | 24.9 |

| XX-A1-3-C1A2-1000-YY | 356 | 1250 | 297 | 1067 | 349 | 1002 | 373 | 963 | 427 | 874 | 56 | 171 | 75 | 27 | 10.2 | 29.7 |

| XX-A1-3-C1A2-1050-YY | 381 | 1300 | 307 | 1137 | 366 | 1066 | 391 | 1025 | 445 | 932 | 56 | 171 | 75 | 27 | 10.7 | 31.1 |

| XX-A1-3-C1A2-1200-YY | 434 | 1450 | 323 | 1295 | 389 | 1212 | 419 | 1166 | 482 | 1058 | 56 | 171 | 75 | 27 | 11.9 | 34.3 |

Note: XX-input for :LS or RS.

YY-Input for angle:20°,30°,35°,45°

Base angle size nominated is normal stock standard. Dimensions F does not vary with change in base angle size.

3 Roll Trough Idlers-offset-114 Diameter

| Code No. | A | B | 20° | 30° | 35° | 45° | E | F | Base Angle Size | Shaft Dia. | Mass R.P. | Total Mass | ||||

| C | D | C | D | C | D | C | D | |||||||||

| XX-A1-3-B1A2-0500-YY | 188 | 750 | 244 | 574 | 272 | 531 | 281 | 508 | 312 | 454 | 56 | 178 | 63 | 27 | 7.2 | 17.8 |

| XX-A1-3-B1A2-0600-YY | 223 | 850 | 257 | 678 | 289 | 626 | 304 | 597 | 336 | 538 | 56 | 178 | 63 | 27 | 8.1 | 19.8 |

| XX-A1-3-B1A2-0650-YY | 243 | 900 | 264 | 738 | 301 | 685 | 317 | 650 | 350 | 594 | 56 | 178 | 63 | 27 | 8.6 | 21.0 |

| XX-A1-3-B1A2-0750-YY | 277 | 1000 | 276 | 834 | 315 | 775 | 333 | 743 | 374 | 670 | 56 | 178 | 63 | 27 | 9.4 | 22.9 |

| XX-A1-3-B1A2-0800-YY | 293 | 1050 | 280 | 880 | 326 | 815 | 345 | 782 | 385 | 710 | 56 | 178 | 63 | 27 | 9.8 | 23.9 |

| XX-A1-3-C1A2-0900-YY | 330 | 1150 | 292 | 986 | 344 | 920 | 369 | 877 | 411 | 800 | 56 | 178 | 75 | 27 | 10.7 | 29.0 |

| XX-A1-3-C1A2-1000-YY | 357 | 1250 | 303 | 1064 | 355 | 996 | 379 | 956 | 432 | 866 | 56 | 178 | 75 | 27 | 11.4 | 31.0 |

| XX-A1-3-C1A2-1050-YY | 382 | 1300 | 313 | 1134 | 372 | 1060 | 397 | 1018 | 450 | 924 | 56 | 178 | 75 | 27 | 12.0 | 32.4 |

| XX-A1-3-C1A2-1200-YY | 435 | 1450 | 329 | 1292 | 395 | 1206 | 425 | 1159 | 487 | 1050 | 56 | 178 | 75 | 27 | 13.3 | 35.7 |

Note:XX-inputfor: LS or RS.

YY-Input for angle: 20°, 30° , 35° ,45°

Base angle size nominated is normal stock standard.Dimensions F does not vary with change in base angle size.

| BEARING | PIPE Dia |

| 6204/6205 | 60/76/89/108/114/127/133 |

| 6305/6306/6307/6308/63096310/6311/6312 | 76/89/108/114/127/133/159/165/194/219 |

RS roller is premium product with triple anti-dust structure which can effectively prevent water and dust. This model applies to the conveyor belt systems that can carry large volume and high speed dusty bulks.

Product Description

heavy duty carrying idler mining conveyor roller

Steel Return Conveyor Roller/Heavy Duty Belt Conveyor Carrying Conveyor Roller/Mining Belt Conveyor Roller Idler

Our products are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries.

|

SPECIFICATIONS |

|

| Diameter | φ89, φ102, φ108, φ114, φ127, φ133, φ139, φ152, φ159, φ165, φ194 |

| Length | 145mm-2800mm |

| Tube | Q235(GB), Q345(GB), welded with DIN2394 standed |

| Shaft | A3 and 45# steel(GB) |

| Bearing | Single & Double Row Deep Groove Ball Bearing 2RS&ZZ with C3 clearance |

| Bearing Housing/Seat | Cold press working fit ISO M7 accuracy

Deep Press steel with raw material fit DIN 1623-1624 standard |

| Lubricating Oil | Grade 2 or 3 long-lasting lithium greasae |

| Welding | Mixed gas shielded arc welding end |

| Painting | Ordinary painting, hot galvanized painting, electric static spraying painting, baked painting |

| Diameter of Tube | Length of Tube | Bearing Type | |

| mm | inch |

mm |

|

| 63.5 | 2 1/2 | 150-3500 | 6204 |

| 76 | 3 | 150-3500 | 6204 6205 |

| 89 | 3 1/2 | 150-3500 | 6204 6205 |

| 102 | 4 | 150-3500 | 6204 6205 6305 |

| 108 | 4 1/4 | 150-3500 | 6204 6205 6305 6306 |

| 114 | 4 1/2 | 150-3500 | 6204 6205 6305 6306 |

| 127 | 5 | 150-3500 | 6204 6205 6305 6306 |

| 133 | 5 1/4 | 150-3500 | 6205 6206 6207 6305 6306 |

| 140 | 5 1/2 | 150-3500 | 6205 6206 6207 6305 6306 |

| 152 | 6 | 150-3500 | 6205 6206 6207 6305 6306 6307 6308 |

| 159 | 6 1/4 | 150-3500 | 6205 6206 6207 6305 6306 6307 6308 |

| 165 | 6 1/2 | 150-3500 | 6207 6305 6306 6307 6308 |

| 177.8 | 7 | 150-3500 | 6207 6306 6307 6308 6309 |

| 190.5 | 7 1/2 | 150-3500 | 6207 6306 6307 6308 6309 |

| 194 | 7 5/8 | 150-3500 | 6207 6307 6308 6309 6310 |

| 219 | 8 5/8 | 150-3500 | 6308 6309 6310 |

About roller,we can make gravity conveyor roller,steel conveyor roller,driving roller,light middle duty conveyor roller,o-belt tapered sleeve roller,gravity tapered roller,polymer sprocket roller and so on.More details,please contact us.

|

Basic Info. |

|

| Model NO. | NS/RS/LS |

| Surface Finishing | Painting, Galvanized or as Your Demand |

| Length | 200-2800mm |

| Colour | as Your Requirement |

| Import Bearings | Lyc(China Famous)NSK, SKF |

| Standard | ISO, Cema, DIN |

| Certification | ISO9001:2015 |

| Ctructure | Conveyor Roller |

| Idler Diameter | 89,108,133,159,194,219mm |

| Color | as Per Your Request |

| Features | Durable ,Power Saving ,etc. |

| Material Feature | Durable |

| After-Sales Service | Engineers Available to Service Machinery Overseas |

| Load Capacity | as Per Order |

| Packaging Details | Wooden Case, Pallet Packaging, Standard Packaging |

| Trademark | GCS, GCS |

| Transport Package | Wooden Box |

| Specification | Customers′ Requirements |

| Origin | Guangdong, China (Mainland) |

| HS Code | 8431390000 |

Roller Idler Application

GCS Conveyor Roller products are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries.

v roller conveyor

Mining Conveyor

Video

Belt Conveyor Roller Idler

Introduction conveyor roller in conveyor

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

1.What is a trough system?

They support conveyor belts by positioning them toward a specific direction, minimizing the potential for deposits spilling over the belt and allowing the belt to hold more deposits.

2.What are trough characteristics?

The primary characteristic of a trough is that it is a region with relatively lower heights.