Massive Selection for 4 Conveyor Rollers - Metal Conveyor Rollers Flat Return Idler | GCS – GCS

Massive Selection for 4 Conveyor Rollers - Metal Conveyor Rollers Flat Return Idler | GCS – GCS Detail:

FLAT CARRY|RETURN IDLERS

As part of our (GCS )GLOBAL CONVEYOR SUPPLIES a wide range of idler assemblies to suit most conveyor applications – engineered according to the highest industry standards.

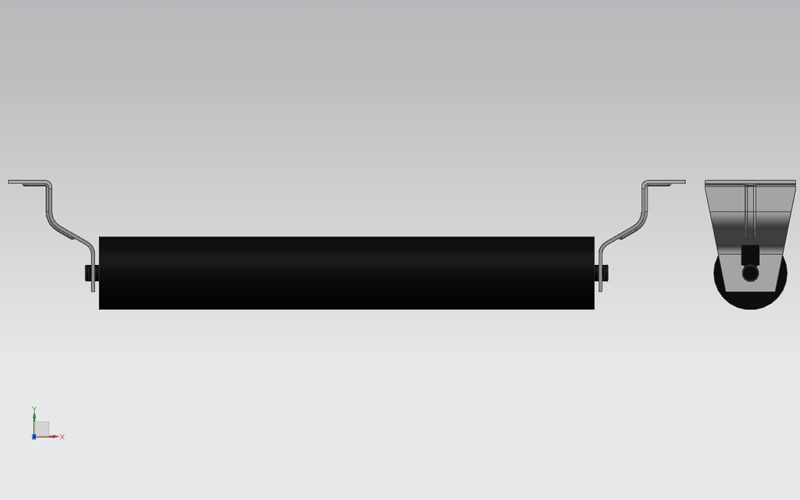

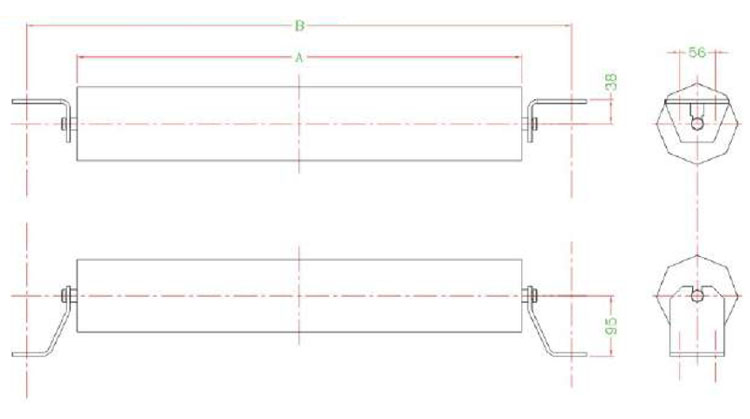

(GCS )GLOBAL CONVEYOR SUPPLIES Flat Return Idler Assemblies are available in 1 or 2 roll configurations, with the 1-roll design being more prevalent. The mass of the return belt is the only load that return idlers are required to support. Idler frame can be customized to suit required belt width. The spacing of these is greater than that of the trough/carry rollers but must be sufficient enough to prevent conveyor belt flap. This distance is usually between 2 and 6 meters.

The return idler are used as support for the return side of belt. Used where materials are not sticky, corrosive, or abrasive.

SPECIFICATION:

For Belt Width: 400-2800mm

Surface Treatment: Electrostatic Powder Coating, Galvanization.

APPLICATION :Mining|Steel mill|Cement plant|Power plant|Chemica|Plant|Sea Port|Storage etc.

CERTIFICATE: ISO9001:2015,

Flat Return Idler -SERIES RS/HRS

FLAT CARRY AND RETURN IDLER-152 DIAMETER

| Code No. | A | B | Series 20 | Series 30 | ||||

| Shaft Dia. | Mass R.P. | Total Mass | Shaft Dia. | Mass R.P. | Total Mass | |||

| XX-A1-1-K0E2-0750-YY | 849 | 1000 | 27 | 13.8 | 20.3 | N/A | N/A | N/A |

| XX-A1-1-K0E2-0800-YY | 899 | 1050 | 27 | 14.5 | 21.2 | N/A | N/A | N/A |

| XX-A1-1-K0E2-0900-YY | 999 | 1150 | 27 | 16.0 | 23.1 | N/A | N/A | N/A |

| XX-A1-1-K0E2-1000-YY | 1099 | 1250 | 27 | 17.5 | 25.0 | 33 | 17.7 | 27.8 |

| XX-A1-1-K0E2-1050-YY | 1149 | 1300 | 30 | 18.4 | 27.4 | 33 | 18.4 | 28.9 |

| XX-A1-1-K0E2-1200-YY | 1299 | 1450 | 30 | 20.4 | 30.2 | 33 | 20.6 | 32.1 |

| XX-A1-1-K0E3-1350-YY | 1499 | 1650 | 33 | 23.4 | 36.1 | 36 | 23.6 | 38.4 |

| XX-A1 K0E3-1400-YY | 1549 | 1700 | 33 | 24.2 | 37.2 | 36 | 24.3 | 39.5 |

| XX-A1-1-K0E3-1500-YY | 1649 | 1800 | 36 | 25.6 | 41.5 | 36 | 25.9 | 41.9 |

| XX-A1-1-K0E5-1600-YY | 1849 | 2000 | 36 | 28.7 | 46.2 | 38 | 29.0 | 48.3 |

| XX-A1-1-K0E5-1800-YY | 2200 | N/A | N/A | N/A | 40 | 32.2 | 57.5 | |

FLAT CARRY AND RETURN IDLER-152 DIAMETER

| Code No. | A | B | Series 45 | Series 55 | ||||

| Shaft Dia. | Mass R.P. | Total Mass | Shaft Dia. | Mass R.P. | Total Mass | |||

| XX-A1-1-K0E2-0900-YY | 1002 | 1150 | 38 | 16.7 | 30.7 | N/A | N/A | N/A |

| XX-A1-1-K0E2-1000-Y Y | 1102 | 1250 | 38 | 18.2 | 31.1 | 48 | 20.1 | 41.0 |

| XX-A1-1-K0E2-1050-YY | 1152 | 1300 | 38 | 19.0 | 34.3 | 48 | 20.8 | 42.4 |

| XX-A1-1-K0E2-1200-YY | 1302 | 1450 | 38 | 21.2 | 37.9 | 48 | 23.0 | 46.8 |

| XX-A1-1-K0E3-1350-YY | 1502 | 1650 | 42 | 24.2 | 45.7 | 48 | 25.9 | 52.5 |

| XX-A1-1-K0E3-1400-YY | 1552 | 1700 | 42 | 25.1 | 47.2 | 48 | 26.6 | 53.9 |

| XX-A1-1-K0E3-1500-YY | 1652 | 1800 | 42 | 26.6 | 49.8 | 48 | 28.1 | 56.9 |

| XX-A1-1-K0E5-1600-YY | 1852 | 2000 | 45 | 29.9 | 58.3 | 48 | 31.0 | 62.6 |

| XX-A1-1-K0E5-1800-YY | 2052 | 2200 | 45 | 33.2 | 64.1 | 48 | 33.9 | 68.3 |

XX-input for: RS or HRS.

For flat carry idlers replace E with H.

For alter native return drop heights refer ide ntificati on system.

Related product

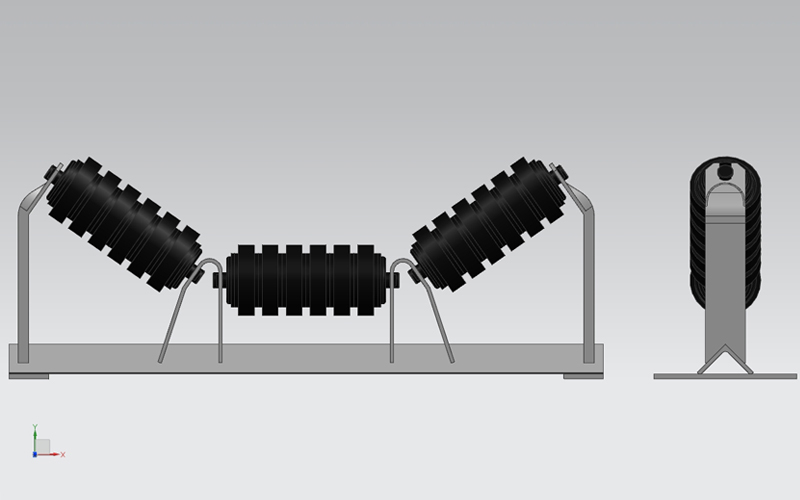

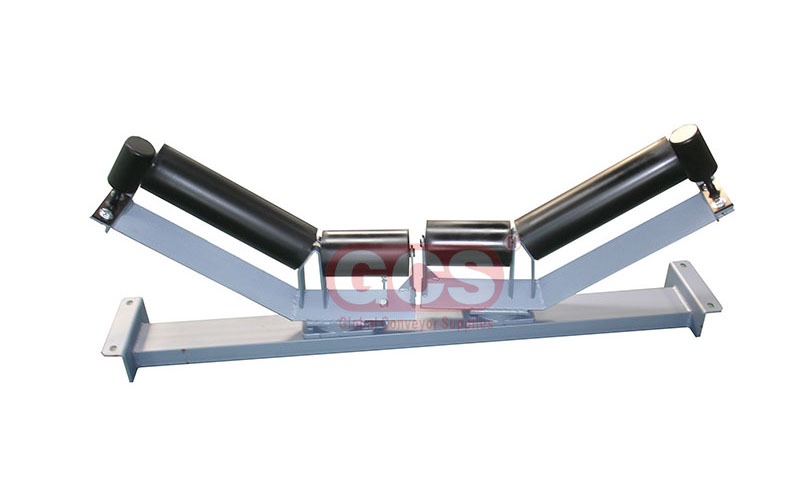

Conveying Rollers Of Trough Rubber Idlers And Bracket

Pipe Diameter Specifications 114 mm V Return Idler

Garland rollers(3roll)for Underground Structure

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

Tell Us Your Requirement About Trough Idler .Contact us Now!

Product detail pictures:

Related Product Guide:

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for Massive Selection for 4 Conveyor Rollers - Metal Conveyor Rollers Flat Return Idler | GCS – GCS , The product will supply to all over the world, such as: French, Poland, Chile, We'll supply much better products with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!