GCS gravity rollers Suppliers Sprocket Roller with Plastic Teeth

GLOBAL CONVEYOR SUPPLIES(GCS) Provides gravity conveyor roller, sprocket roller, grooved roller, and tapered rollers, which are available in many sizes with a number of different configurations. Multiple bearing options, drive options, accessories, assembly options, coatings, and more allow us to accommodate almost any application. Rollers can be custom-built for extreme temperature ranges, heavy loads, high speeds, dirty, corrosive, and wash-down environments.

Our goal is to supply a roller that will last longer, work better, and is built to whatever size the customer needs. We want to be your one-stop shop for all of your conveyor roller solutions.

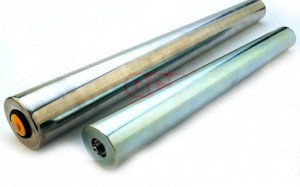

Plastic Sleeve Sprocket Roller

| Model (Roller Dia) | (T) | Shaft Dia | Sprocket | Roller length | Tube Material | Surface Finishing |

| SLS50 | T=1.2, 1.5 | φ12 |

14 tooth x 1/2" pitch according to customers' requirement |

300-1500 | Carbon Steel Stainless Steel

PVC |

Zinc plated Chrome plated |

| SLS60 | T=2.0 | φ12 15 | 300-1500 | |||

| SLS76 | T=2.0 3.0 | φ15φ20 | 300-1500 |

Center axis condition

Round

Un-machined round spindles are suitable for double spring-loaded rollers. In some cases, the side frames could be drilled as opposed to punched.

Drilled Spindle End

'Cross drilled' spindles are supplied loose and allow several rollers to be wired together in a side frame to prevent spindle rotation and retain the roller.

Drilled and Tapped

Both round and hexagonal spindles can be drilled and tapped at each end to enable the roller to be bolted between the conveyor side frames, thus increasing the rigidity of the conveyor.

Milled Flats

Round spindles with 2 milled flats are used in conveyors with slotted side frames where rollers are lowered into position. In most cases, the spindle is supplied fixed within the roller.

Circlipped

External circlips can be used to captivate a spindle within a roller. This method of retention is usually found on heavy-duty rollers and drums.

Threaded

Round spindles can be threaded at either end to suit a metric or imperial nut. In most cases, the spindle is supplied loose.

Hexagonal

Extruded hexagonal spindles are suitable for punched conveyor side frames. In most cases, the spindle would be spring-loaded. The hexagonal shape prevents the spindle from rotating in the side frame, it also prevents the bearing inner race from rotating on the spindle.

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

1.What is a gravity roller conveyor?

A gravity roller conveyor lets a product move on rollers using the force of gravity to move the load. Gravity conveyors are one of the simplest and affordable types of material handling systems.

2.How are roller conveyors powered?

With powered roller conveyors, some or all of a conveyor’s rollers are powered to propel the product down the line. In a typical system, one in nine rollers is powered by an internal motor and linked to the non-powered rollers with a series of O-rings.

3.How do I choose conveyor rollers?

According to the different transportation materials and use scenarios, we can choose different materials and different power situation conveyor. Please find more details in How do I choose a roller conveyor?