Factory source Tapered Rollers Conveyor - GCS conveyor roller factory Impact Roller Set with bracket – GCS

Factory source Tapered Rollers Conveyor - GCS conveyor roller factory Impact Roller Set with bracket – GCS Detail:

GCS Conveyor Supply offers a wide range of rollers to fit most conveyor applications – designed to the highest industry standards. Roller materials, lengths, diameters, and trough options can be customized to meet customer specifications. We are a manufacturer of slotted rollers, rollers, and frames. Our factory can do it all for bulk material companies, making it simple for everyone to design and order custom rollers and affordable matching roller frames online.

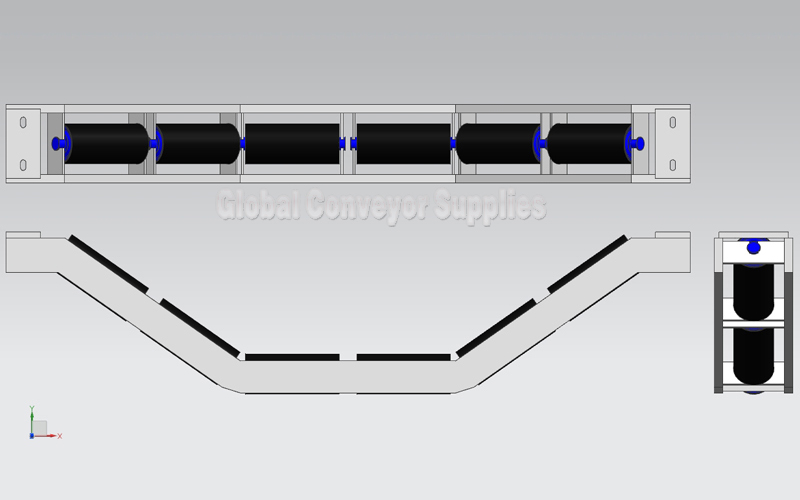

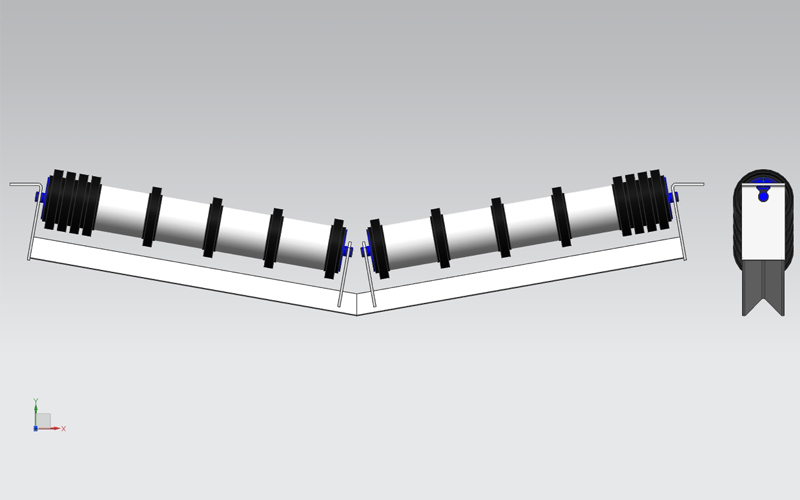

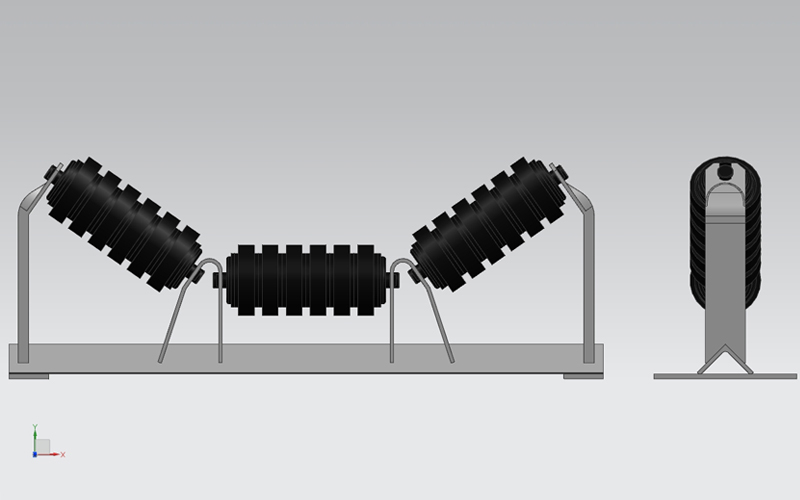

The Equal Trough impact idler, a conventional type carrier roller set, consists of three equal-length impact idlers supporting three rollers in one frame that is fixed to the conveyor structure. In quarry and mining applications, when large, heavy, and sharp materials fall on the conveyor, they can impact and damage the belt, ultimately leading to downtime and higher replacement costs. Therefore, an impact idler is needed in the material impact area.

It is designed with a rubber ring to provide cushioning and absorb impact in the material impact area, minimizing damage to the belt.

The impact idler sets are typically spaced 350 mm to 450 mm apart to provide overall support. It is installed in the first roller group at the conveyor’s drop gate.

Applications

Conveyor impact rollers are used for belt conveyors to receive materials and reduce and slow down the impact of the conveyor belt, mainly designed for corrosive environments such as coal washing plants, coking plants, and chemical plants. The impact rollers have good corrosion resistance and if used in corrosive situations, their service life is five times that of ordinary rollers.

Get high-quality conveyor rollers, custom conveyor rollers, matching roller supports, and more you need.

The roller set with anti-sticking rubber roller and roller frame is used in heavy bulk roller idler conveyors|GCS

impact rollers are used and positioned corresponding to the load points, where the lumps and the weight of material fling onto the belt could cause damage to it. To limit the impact effect of the material onto the rollers, the platters are covered with a series of rubber rings of adequate thickness and resistance.

Material Iron

Application Chemical Industry| Grain Transportation|Mining Transport|

Power Plant|Structure

Ordinary Roller|Bearing Type|D Double-SealedBearing

Type: Impact Idler

Product Name: Impact Idler Roller

Usage: Conveyor Belt System

Diameter:50-219 mm

Surface Preparation: Spray Paint

Color: Requirements

Certification: ISO 9001:2015

Trademark: GCS Brand

HS Code:8431390000

Trough Eccentric Idler – SERIES LS/RS

3 ROLL TROUGH IDLERS-127 DIAMETER

| Code No. | A | B | 20° | 30° | 35° | 45° | Base Angle Size | Shaft Dia. | Trough Mass | Total | Shaft Dia. | Impact Mass R.P. | Total Mass | ||||

| C | D | C | D | C | D | C | D | R.P. | Mass | ||||||||

| XX-A1-3-C2A2-0750-YY | 278 | 1000 | 105 | 860 | 145 | 828 | 165 | 794 | 196 | 710 | 75 | 27 | 11.0 | 29.1 | 27 | 13.5 | 34.6 |

| XX-A1-3-C2A2-0800-YY | 294 | 1050 | 105 | 914 | 160 | 870 | 180 | 830 | 208 | 752 | 75 | 27 | 11.7 | 30.1 | 27 | 14.1 | 36.0 |

| XX-A1-3-C2A2-0900-YY | 331 | 1150 | 118 | 1020 | 177 | 972 | 198 | 934 | 238 | 834 | 75 | 27 | 12.5 | 32.1 | 27 | 15.3 | 38.7 |

| XX-A1-3-C2A2-1000-YY | 358 | 1250 | 128 | 1096 | 190 | 1048 | 217 | 1000 | 259 | 898 | 75 | 27 | 13.3 | 34.1 | 27 | 16.5 | 41.5 |

| XX-A1-3-C2A2-1050-YY | 383 | 1300 | 143 | 1166 | 206 | 1114 | 228 | 1070 | 273 | 962 | 75 | 27 | 14.0 | 35.6 | 27 | 17.6 | 43.6 |

| XX-A1-3-C2A2-1200-YY | 436 | 1450 | 158 | 1318 | 226 | 1262 | 262 | 1240 | 314 | 1084 | 75 | 27 | 15.5 | 39.3 | 27 | 20.0 | 48.9 |

| XX-A1-3-D2A3-1350-YY | 488 | 1650 | 178 | 1466 | 257 | 1402 | 285 | 1350 | 349 | 1212 | 90 | 30 | 17.1 | 46.6 | 30 | 22.3 | 58.2 |

| XX-A1-3-D2A3-1400-YY | 494 | 1700 | 178 | 1488 | 257 | 1424 | 297 | 1354 | 349 | 1240 | 90 | 30 | 17.2 | 47.5 | 30 | 22.6 | 59.2 |

| XX-A1-3-E2A3-1500-YY | 541 | 1800 | 193 | 1622 | 289 | 1540 | 318 | 1486 | 392 | 1328 | 100 | 30 | 18.6 | 57.4 | 30 | 24.7 | 71.6 |

| XX-A1-3-E2A5-1600-YY | 561 | 2000 | 193 | 1684 | 289 | 1602 | 336 | 1530 | 392 | 1406 | 100 | 33 | 19.2 | 62.5 | 33 | 25.6 | 77.6 |

Note: XX-inputfor: RS or HRS.

YY-Inputforangle: 20° ,30° ,35° ,45°

Base angle size nominated is normal stock standard. Dimensions E and F do not vary with change in base angle size as tabulated below.

Code numbers shown are for plain trough idlers, for impact idlers change both” A’s” in code numbers to ” B’s

SERIES RS/HRS 3 ROLL TROUGH IDLERS-127 DIAMETER

| Code No. | A | B | 20° | 30° | 35° | 45° | Base Angle Size | Shaft Total | Trough Mass | Total | Shaft Dia. | Impact Mass R.P. | Total Mass | ||||

| C | D | C | D | C | D | C | D | Dia. | R.P. | Mass | |||||||

| XX-A1-3-C2A2-1000-YY | 359 | 1250 | 128 | 1096 | 190 | 1048 | 217 | 1000 | 259 | 898 | 75 | 27 | 15.0 | 36.2 | 27 | 16.5 | 41.9 |

| XX-A1-3-C2A2-1050-YY | 384 | 1300 | 143 | 1166 | 206 | 1114 | 228 | 1070 | 273 | 962 | 75 | 27 | 15.8 | 37.6 | 27 | 17.6 | 43.8 |

| XX-A1-3-D2A2-1200-YY | 437 | 1450 | 158 | 1318 | 226 | 1262 | 262 | 1240 | 314 | 1084 | 90 | 27 | 17.3 | 43.3 | 27 | 20.0 | 51.6 |

| XX-A1-3-D2A3-1350-YY | 489 | 1650 | 178 | 1466 | 257 | 1402 | 285 | 1350 | 349 | 1212 | 90 | 30 | 18.8 | 48.7 | 30 | 22.3 | 58.6 |

| XX-A1-3-D2A3-1400-YY | 496 | 1700 | 178 | 1488 | 257 | 1424 | 297 | 1354 | 349 | 1240 | 90 | 30 | 19.0 | 49.5 | 30 | 22.6 | 59.7 |

| XX-A1-3-E2A3-1500-YY | 542 | 1800 | 193 | 1622 | 289 | 1540 | 318 | 1486 | 392 | 1328 | 100 | 30 | 20.4 | 59.4 | 30 | 24.7 | 71.8 |

| XX-A1-3-F2A5-1600-YY | 562 | 2000 | 193 | 1684 | 289 | 1602 | 336 | 1530 | 392 | 1406 | 125 | 33 | 21.0 | 71.5 | 33 | 25.6 | 87.4 |

| XX-A1-3-F2A5-1800-YY | 626 | 2200 | 223 | 1860 | 325 | 1770 | 371 | 1700 | 439 | 1560 | 125 | 33 | 22.8 | 78.1 | 33 | 28.5 | 96.5 |

Note: XX-inputfor: RS or HRS.

YY-Input for angle: 20°, 30° ,35° ,45°

Base angle size nominated is normal stock standard.Dimensions E and F do not vary with change in base angle size as tabulated below.

Code numbers shown are for plain trough idlers,for impact idlers change both” A’sn in code numbers to ” B*s

| Base Angle | E | F |

| 75X75X6 | 165 | 222 |

| 90X90X7 | 180 | 232 |

| 100X100X8 | 200 | 240 |

| 125X125X8 | 240 | 260 |

| 140X140X12 | 280 | 279 |

We are partners of our customers from first contact to after-sales service. As a technical consultant, we discuss the requirements with our customers and develop solutions that increase the efficiency and added-value. Along the entire – ISO 9001 certified process chain – we offer the most attractive solution package.

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

Tell Us Your Requirement About Trough Idler .Contact us Now!

Related product

Rubber Disc Return Idler

Bearing Rollers Suppliers Of the V Return Idler

Conveyor System Cone self-aligning roller

Related article

GCS belt conveyor types and application principle

Roller Conveyor Manufacturing and Supply by (GCS)Global Conveyor Supplies

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

Tell Us Your Requirement About Conveyor Roller .Contact us Now!

G C S conveyor roller Series

Model: RS62 63 SERIES

Specification

| Name | Belt Conveyor Impact Idler Specifications |

| Standard | DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc. |

| Shaft Diameter | 20, 25, 30, 35, 40, 45, 50mm |

| Roller Diameter | 89, 102, 108, 114, 127, 133, 140, 152, 159, 165, 178, 194, 217mm |

| Roller Length | 190-1600mm |

| Bearing brand | SKF, NSK, FAG, HRB, LYC, ZWZ, C&U |

| Color | Customized |

| BEARING | PIPE Dia |

| 6204/6205 | 60/76/89/108/114/127/133 |

| 6305/6306/6307/6308/63096310/6311/6312 | 76/89/108/114/127/133/159/165/194/219 |

RS roller is premium product with triple anti-dust structure which can effectively prevent water and dust. This model applies to the conveyor belt systems that can carry large volume and high speed dusty bulks.

Product Description

heavy duty carrying idler mining conveyor roller

Steel Return Conveyor Roller/Heavy Duty Belt Conveyor Carrying Conveyor Roller/Mining Belt Conveyor Roller Idler

Our products are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries.

|

SPECIFICATIONS |

|

| Diameter | φ89, φ102, φ108, φ114, φ127, φ133, φ139, φ152, φ159, φ165, φ194 |

| Length | 145mm-2800mm |

| Tube | Q235(GB), Q345(GB), welded with DIN2394 standed |

| Shaft | A3 and 45# steel(GB) |

| Bearing | Single & Double Row Deep Groove Ball Bearing 2RS&ZZ with C3 clearance |

| Bearing Housing/Seat | Cold press working fit ISO M7 accuracy

Deep Press steel with raw material fit DIN 1623-1624 standard |

| Lubricating Oil | Grade 2 or 3 long-lasting lithium greasae |

| Welding | Mixed gas shielded arc welding end |

| Painting | Ordinary painting, hot galvanized painting, electric static spraying painting, baked painting |

| Diameter of Tube | Length of Tube | Bearing Type | |

| mm | inch |

mm |

|

| 63.5 | 2 1/2 | 150-3500 | 6204 |

| 76 | 3 | 150-3500 | 6204 6205 |

| 89 | 3 1/2 | 150-3500 | 6204 6205 |

| 102 | 4 | 150-3500 | 6204 6205 6305 |

| 108 | 4 1/4 | 150-3500 | 6204 6205 6305 6306 |

| 114 | 4 1/2 | 150-3500 | 6204 6205 6305 6306 |

| 127 | 5 | 150-3500 | 6204 6205 6305 6306 |

| 133 | 5 1/4 | 150-3500 | 6205 6206 6207 6305 6306 |

| 140 | 5 1/2 | 150-3500 | 6205 6206 6207 6305 6306 |

| 152 | 6 | 150-3500 | 6205 6206 6207 6305 6306 6307 6308 |

| 159 | 6 1/4 | 150-3500 | 6205 6206 6207 6305 6306 6307 6308 |

| 165 | 6 1/2 | 150-3500 | 6207 6305 6306 6307 6308 |

| 177.8 | 7 | 150-3500 | 6207 6306 6307 6308 6309 |

| 190.5 | 7 1/2 | 150-3500 | 6207 6306 6307 6308 6309 |

| 194 | 7 5/8 | 150-3500 | 6207 6307 6308 6309 6310 |

| 219 | 8 5/8 | 150-3500 | 6308 6309 6310 |

About roller,we can make gravity conveyor roller,steel conveyor roller,driving roller,light middle duty conveyor roller,o-belt tapered sleeve roller,gravity tapered roller,polymer sprocket roller and so on.More details,please contact us.

|

Basic Info. |

|

| Model NO. | NS/RS/LS |

| Surface Finishing | Painting, Galvanized or as Your Demand |

| Length | 200-2800mm |

| Colour | as Your Requirement |

| Import Bearings | Lyc(China Famous)NSK, SKF |

| Standard | ISO, Cema, DIN |

| Certification | ISO9001:2015 |

| Ctructure | Conveyor Roller |

| Idler Diameter | 89,108,133,159,194,219mm |

| Color | as Per Your Request |

| Features | Durable ,Power Saving ,etc. |

| Material Feature | Durable |

| After-Sales Service | Engineers Available to Service Machinery Overseas |

| Load Capacity | as Per Order |

| Packaging Details | Wooden Case, Pallet Packaging, Standard Packaging |

| Trademark | GCS, GCS |

| Transport Package | Wooden Box |

| Specification | Customers′ Requirements |

| Origin | Guangdong, China (Mainland) |

| HS Code | 8431390000 |

Roller Idler Application

GCS Conveyor Roller products are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries.

v roller conveyor

Mining Conveyor

Video

Belt Conveyor Roller Idler

Introduction conveyor roller in conveyor

Product detail pictures:

Related Product Guide:

Attaining consumer satisfaction is our company's purpose without end. We will make wonderful endeavours to produce new and top-quality merchandise, satisfy your exclusive requirements and supply you with pre-sale, on-sale and after-sale services for Factory source Tapered Rollers Conveyor - GCS conveyor roller factory Impact Roller Set with bracket – GCS , The product will supply to all over the world, such as: Angola, Libya, Armenia, Our professional engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to give you the ideal service and goods. For anyone who is thinking about our company and merchandise, please contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Please feel free to get in touch with us for business and we believe we are going to share the top trading practical experience with all our merchants.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.