Roller Conveyor System Design packaging line | GCS

GCS- Roller Conveyor System Design

Roller Conveyor System Design packaging line

Roller Conveyor Manufacturing and Supply by (GCS)CONVEYOR

Roller conveyors are a versatile option that allows for objects of various sizes to be moved quickly and efficiently. We're not a catalog-based company, so we're able to tailor the width, length, and functionality of your roller conveyor system to suit your layout and production goals.

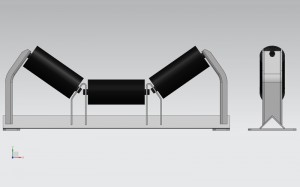

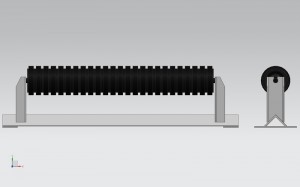

Conveyor Rollers

(GCS drive conveyor roller manufacturers)Conveyors offer a wide range of rollers to suit your particular application. Whether you require sprocket, grooved, gravity, or tapered rollers, we can custom build a conveyor system for your needs. We can also create specialty rollers for high-speed output, heavy loads, extreme temperatures, corrosive environments, and other specialized applications.

Gravity Roller Conveyors

For applications that require a non-powered means of conveying items, Gravity Controlled Rollers make an excellent choice for permanent and temporary conveyor lines. Often used on production lines, warehouses, assembly facilities, and shipping/sorting facilities, this type of roller is versatile enough to accommodate a wide range of applications.

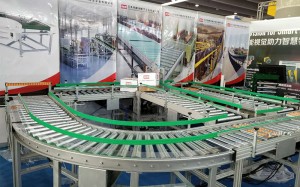

Gravity Curved Rollers

By adding a Gravity Curved Roller, businesses are able to take advantage of their space and layout in a way that straight rollers cannot. Curves allow for a smooth product flow, enabling you to make use of room corners. Rail guards may also be added for additional product protection, and tapered rollers can be installed to ensure proper product orientation.

Line shaft Conveyors

For applications where accumulation and product sorting are important, Line shaft Conveyors are the most popular choice. This type of conveyor requires little upkeep, and also accommodates wash-down applications through the use of stainless, PVC, or galvanized components.

Conveyor roller:

Multiple transmission modes: gravity, flat belt, O-belt, chain, synchronous belt, multi-wedge belt, and other Linkage components. It can be used in various types of conveyor systems, and it is suitable for speed regulation, light-duty, medium-duty, and heavy-duty loads. Multiple materials of roller: zinc-plated carbon steel, chrome-plated carbon steel, stainless steel, PVC, aluminum, and rubber coating or lagging. Roller specifications can be customized according to requirements

Retractable conveyor chain video

GCS-Roller Type

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.