Conveyor impact idler with rubber for mining equipment

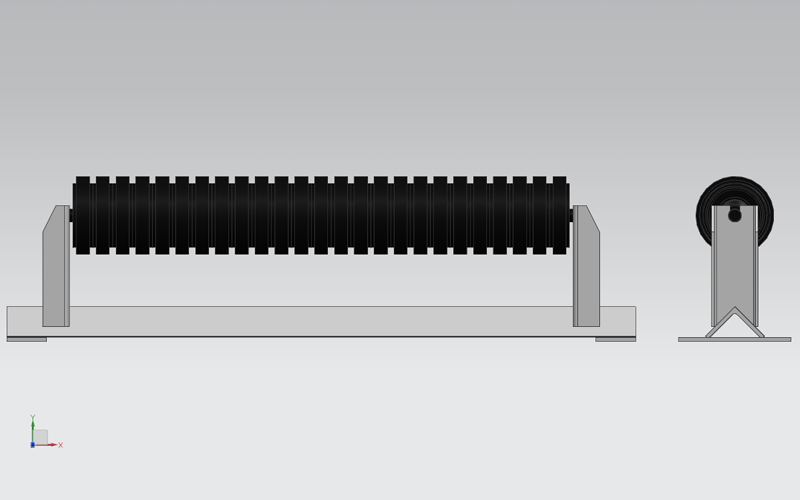

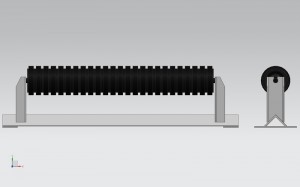

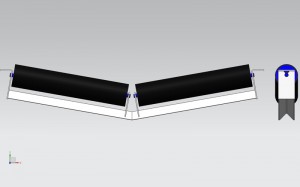

Flat Impact idler

Flat impact idler is composed of a single impact roller. The aggregate conveyor roller surface is covered with rubber to absorb the impact kinetic energy on the conveyor belt when conveying materials fall down and extend the working life of the conveyor belt. which is mainly used for carrying packaged articles.

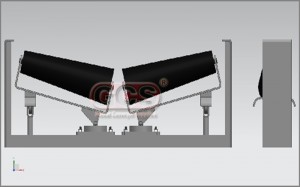

Rubber disc return idlers

A big concern in applications with sticky material is removing material that has become affixed to the belt.

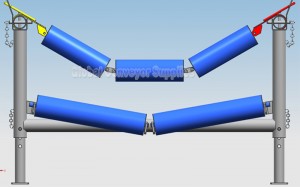

Roller flat return carry idler set

roller dia(mm). 102-/114/127/152/178/194 or customization bearing type:6204 6205 6305 6306 6307 6308 6309

GCS Conveyor roller suppliers are professional China conveying equipment manufacturers. If you have any inquiries, welcome to contact us for an accurate quotation.

Flat Impact Idler - SERIES RS/HRS

FLAT IMPACT IDLER 133 DIAMETER

| Code No. | A | B | No.of Discs | Shaft Dia. | M 只.P. | Total Mass |

| XX-B1-1-K0H2-0500-YY | 580 | 750 | 23 | 27 | 9.2 | 14.5 |

| XX-B1-1-K0H2-0600-YY | 680 | 850 | 27 | 27 | 10.7 | 16.4 |

| XX-B1-1-K0H2-0650-YY | 730 | 900 | 29 | 27 | 11.5 | 17.4 |

| XX-B1-1-K0H2-0750-YY | 830 | 1000 | 33 | 27 | 13.0 | 19.4 |

| XX-B1-1-K0H2-0800-YY | 880 | 1050 | 36 | 27 | 14.0 | 20.6 |

| XX-B1-1-K0H2-0900-YY | 980 | 1150 | 40 | 27 | 15.5 | 22.6 |

| XX-B1-1-K0H2-1000-YY | 1080 | 1250 | 44 | 27 | 17.1 | 24.6 |

| XX-B1-1-K0H2-1050-YY | 1130 | 1300 | 46 | 30 | 17.9 | 26.9 |

| XX-B1-1-K0H2-1200-YY | 1280 | 1450 | 52 | 30 | 20.2 | 30.0 |

| XX-B1-1-K0H3-1350-YY | 1480 | 1650 | 60 | 33 | 23.3 | 36.0 |

| XX-B1-1-K0H3-1400-YY | 1530 | 1700 | 62 | 33 | 25.0 | 38.1 |

Note: XX-input for: RS or HRS.

FLAT IMPACT IDLER 159 DIAMETER

| Code No. | A | B | No.of Discs | Shaft Dia. | M 只.P. | Total Mass |

| XX-B1 -1-K0H2-0600-YY | 685 | 850 | 18 | 38 | 16.0 | 27.4 |

| XX-B1-1-K0H2-0650-YY | 735 | 900 | 19 | 38 | 17.4 | 29.2 |

| XX-B1-1-K0H2-0750-YY | 835 | 1000 | 22 | 38 | 19.8 | 32.5 |

| XX-B1-1-K0H2-0800-YY | 885 | 1050 | 23 | 38 | 20.8 | 33.9 |

| XX-B1-1-K0H2-0900-YY | 985 | 1150 | 26 | 38 | 23.2 | 37.2 |

| XX-B1-1-K0H2-1000-YY | 1085 | 1250 | 29 | 38 | 25.7 | 40.6 |

| XX-B1-1-K0H2-1050-YY | 1135 | 1300 | 30 | 38 | 26.6 | 42.0 |

| XX-B1-1-K0H2-1200-Y Y | 1285 | 1450 | 34 | 38 | 30.0 | 46.7 |

| XX-B1-1-K0H3-1350-YY | 1485 | 1650 | 39 | 38 | 34.4 | 52.9 |

| XX-B1-1-K0H3-1400-YY | 1535 | 1700 | 41 | 38 | 35.8 | 54.7 |

| XX-B1-1-K0H3-1500-YY | 1635 | 1800 | 44 | 38 | 38.3 | 58.1 |

| XX-B1-1-K0H5-1600-YY | 1835 | 2000 | 49 | 38 | 42.6 | 64.2 |

| XX-B1-1-K0H5-1800-YY | 2035 | 2200 | 54 | 42 | 47.1 | 70.5 |

FLAT IMPACT IDLER 178 DIAMETER

| Code No. | A | B | No.of Discs | Shaft Dia. | M只・P. | Total Mass |

| XX-B1-1-K0H2-0600-YY | 685 | 850 | 18 | 38 | 18.5 | 29.9 |

| XX-B1-1-K0H2-0650-YY | 735 | 900 | 19 | 38 | 20.1 | 31.9 |

| XX-B1-1-K0H2-0750-YY | 835 | 1000 | 22 | 38 | 22.9 | 35.6 |

| XX-B1-1-K0H2-0800-YY | 885 | 1050 | 23 | 38 | 24.0 | 37.1 |

| XX-B1-1-K0H2-0900-YY | 985 | 1150 | 26 | 38 | 26.8 | 40.8 |

| XX-B1-1-K0H2-1000-YY | 1085 | 1250 | 29 | 38 | 29.8 | 44.7 |

| XX-B1-1-K0H2-1050-YY | 1135 | 1300 | 30 | 38 | 30.8 | 46.2 |

| XX-B1-1-K0H2-1200-YY | 1285 | 1450 | 34 | 38 | 34.8 | 51.5 |

| XX-B1-1-K0H3-1350-YY | 1485 | 1650 | 39 | 38 | 39.9 | 58.4 |

| XX-B1-1-K0H3-1400-YY | 1535 | 1700 | 41 | 38 | 41.5 | 60.4 |

| XX-B1-1-K0H3-1500-YY | 1635 | 1800 | 44 | 38 | 44.5 | 64.3 |

| XX-B1-1-K0H5-1600-YY | 1835 | 2000 | 49 | 38 | 49.5 | 71.1 |

| XX-B1-1-K0H5-1800-YY | 2035 | 2200 | 54 | 42 | 54.6 | 78.0 |

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.