Factory Outlets Steel Rollers - Wholesale Mining Equipment Conveyor Trough Impact Roller | GCS – GCS

Factory Outlets Steel Rollers - Wholesale Mining Equipment Conveyor Trough Impact Roller | GCS – GCS Detail:

GCS Conveyor Supply offers a wide range of rollers to fit most conveyor applications – designed to the highest industry standards. Roller materials, lengths, diameters, and trough options can be customized to meet customer specifications. We are a manufacturer of slotted rollers, rollers, and frames. Our factory can do it all for bulk material companies, making it simple for everyone to design and order custom rollers and affordable matching roller frames online.

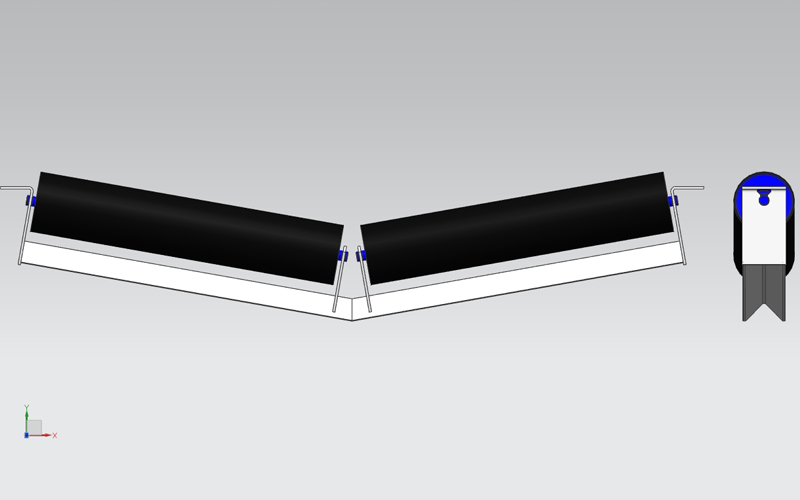

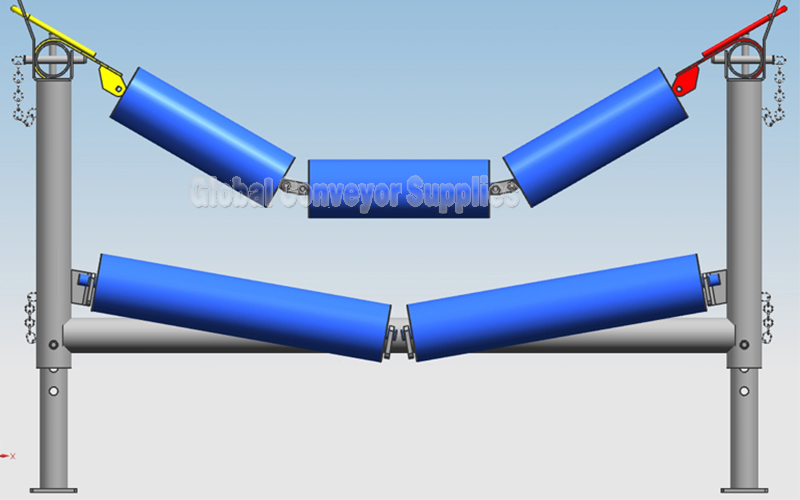

The Equal Trough impact idler, a conventional type carrier roller set, consists of three equal-length impact idlers supporting three rollers in one frame that is fixed to the conveyor structure. In quarry and mining applications, when large, heavy, and sharp materials fall on the conveyor, they can impact and damage the belt, ultimately leading to downtime and higher replacement costs. Therefore, an impact idler is needed in the material impact area.

It is designed with a rubber ring to provide cushioning and absorb impact in the material impact area, minimizing damage to the belt.

The impact idler sets are typically spaced 350 mm to 450 mm apart to provide overall support. It is installed in the first roller group at the conveyor’s drop gate.

Applications

Conveyor impact rollers are used for belt conveyors to receive materials and reduce and slow down the impact of the conveyor belt, mainly designed for corrosive environments such as coal washing plants, coking plants, and chemical plants. The impact rollers have good corrosion resistance and if used in corrosive situations, their service life is five times that of ordinary rollers.

Get high-quality conveyor rollers, custom conveyor rollers, matching roller supports, and more you need.

Belt Conveyor Trough Impact Roller Set Application In Mining Equipment Roller Idler Conveyor |GCS idler roller manufacturer

Model NO. DTII TD 75

Material Iron

Application Chemical Industry| Grain Transportation|Mining Transport|

Power Plant|Structure

Ordinary Roller|Bearing Type| Double-Sealed Bearing

Type: Impact Idler

Product Name: Impact Idler Roller

Usage: Conveyor Belt System

Diameter:50-219 mm

Surface Preparation: Spray Paint

Color: Requirements

Certification: ISO 9001: 2015

Trademark: GCS Brand

HS Code:8431390000

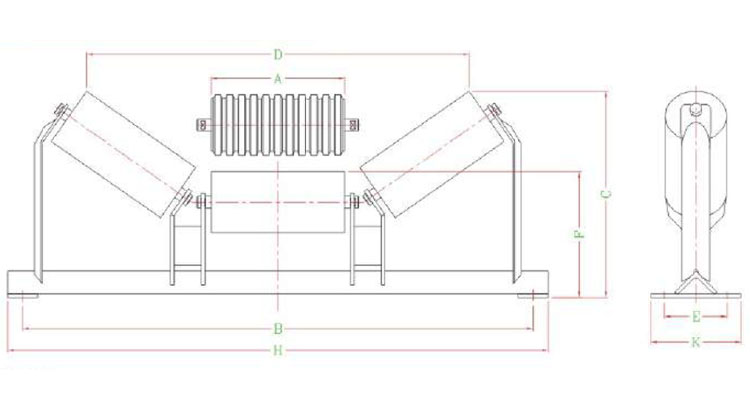

Trough Idler -SERIES RS/HRS

3 ROLL TROUGH IDLERS-152 DIAMETER

| Code No. | A | B | 20° | 30° | 35° | 45° | Base Angle Size | Shaft Dia. | Trough Mass R.P. | Total Mass | Shaft Dia. | Impact Mass R.P. | Total Mass | ||||

| C | D | C | D | C | D | C | D | ||||||||||

| XX-A1-3-D3A2-1200-YY | 442 | 1450 | 158 | 1334 | 231 | 1276 | 267 | 1214 | 319 | 1086 | 90 | 38 | 26.6 | 62.7 | 38 | 32.4 | 74.1 |

| XX-A1-3-E3A3-1350-YY | 494 | 1650 | 178 | 1480 | 261 | 1408 | 295 | 1350 | 354 | 1214 | 100 | 38 | 2&9 | 74.6 | 38 | 35.2 | 87.9 |

| XX-A1-3-E3A3-1400-YY | 500 | 1700 | 178 | 1500 | 261 | 1432 | 295 | 1372 | 354 | 1232 | 100 | 38 | 29.2 | 75.6 | 38 | 35.7 | 89.7 |

| XX-A1-3-E3A3-1500-YY | 547 | 1800 | 192 | 1636 | 291 | 1554 | 320 | 1500 | 387 | 1350 | 100 | 38 | 3.2 | 80.5 | 38 | 39.1 | 96.5 |

| XX-A1-3-F3A5-1600-YY | 567 | 2000 | 192 | 1696 | 291 | 1616 | 340 | 1540 | 409 | 1386 | 125 | 38 | 32.1 | 91.6 | 38 | 39.9 | 110.7 |

| XX-A1-3-F3A5-1800-YY | 631 | 2200 | 227 | 1874 | 330 | 1786 | 375 | 1714 | 443 | 1562 | 125 | 38 | 34.9 | 99.6 | 38 | 44.8 | 122.2 |

| XX-A1-3-G3A5-2000-YY | 706 | 2400 | 247 | 2090 | 366 | 1988 | 411 | 1918 | 492 | 1748 | 140 | 38 | 38.2 | 124.4 | 38 | 49.3 | 154.3 |

| XX-A1-3-G3A5-2200-YY | 785 | 2600 | 277 | 2318 | 407 | 2206 | 465 | 2112 | 556 | 1926 | 140 | 42 | 41.7 | 138.8 | 42 | 54.9 | 172.7 |

Note:XX-inputfor: RS or HRS.

YY-Inputforangle: 20° , 30° , 35° ,45°

Base angle size nominated is normal stock standard. Dimensions E and F vary with change in base angle size as tabulated below.

Code numbers shown are for plain trough idlers,for impact idlers change both” A’sH in code numbers to ” B’s

SERIES RS/HRS 3 ROLL TROUGH IDLERS-152 DIAMETER

| Code No. | A | B | 20° | 30° | 35° | 45° | Base Angle Size | Shaft Dia. | Trough Mass R.P. | Total Mass | Shaft Dia. | Impact Mass R.P. | Total Mass | ||||

| C | D | C | D | C | D | C | D | ||||||||||

| XX-A1-3-F3A5-1600-YY | 569 | 2000 | 192 | 1326 | 229 | 1263 | 265 | 1200 | 315 | 1068 | 90 | 38 | 42.0 | 78.1 | 38 | 38.7 | 83.7 |

| XX-A1-3-F3A5-1800-YY | 633 | 2200 | 227 | 1472 | 259 | 1395 | 293 | 1336 | 350 | 1196 | 100 | 38 | 46.0 | 91.7 | 38 | 42.7 | 98.7 |

| XX-A1-3-G3A5-2000-YY | 708 | 2400 | 247 | 1492 | 259 | 1419 | 293 | 1358 | 350 | 1214 | 100 | 38 | 46.4 | 92.9 | 38 | 43.3 | 100.5 |

| XX-A1-3-G3A5-2200-YY | 787 | 2600 | 277 | 1628 | 289 | 1541 | 318 | 1486 | 383 | 1332 | 100 | 38 | 50.0 | 99.3 | 38 | 47.3 | 107.4 |

| XX-A1-3-G3A5-2400-YY | 848 | 2800 | 294 | 1688 | 289 | 1603 | 338 | 1526 | 405 | 1368 | 125 | 38 | 51.5 | 111.0 | 38 | 48.7 | 122.3 |

| XX-A1-3-G3A5-2500-YY | 873 | 2900 | 304 | 1888 | 328 | 1773 | 373 | 1700 | 439 | 1544 | 125 | 38 | 56.4 | 121.1 | 38 | 54.3 | 133.8 |

| XX-A1-3-G3A5-2600-YY | 905 | 3000 | 322 | ||||||||||||||

| XX-A1-3-G3A5-2800-YY | 984 | 3200 | 348 | 2082 | 364 | 1975 | 409 | 1904 | 488 | 1730 | 140 | 38 | 62.2 | 148.3 | 42 | 60.5 | 167.1 |

| XX-A1-3-G3A5-3000-YY | 1050 | 3400 | 369 | 2310 | 405 | 2193 | 463 | 2098 | 552 | 1918 | 140 | 42 | 68.2 | 165.3 | 42 | 67.1 | 186.0 |

Note: XX-input for: RS or HRS.

YY-Input for angle: 20°, 30°, 35°,45°

Base angle size nominated is normal stock standard. Dimensions E and F do not vary with change in base angle size as tabulated.

Code numbers shown are for plain trough idlers, for impact idlers change both” A’s” in code numbers to ” B’s

| Base Angle | E | F |

| 75x75x6 | 165 | 247 |

| 90x90x7 | 180 | 257 |

| 100x100x8 | 200 | 267 |

| 125x125x8 | 240 | 286 |

| 140x140x12 | 280 | 305 |

GCS conveyor idler manufacturers reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

Tell Us Your Requirement About Trough Idler .Contact us Now!

Related product

Steel Garland Rollers 6roll by GCS

Adjustment Friction roller Trough and return by GCS

Trough type 45|35 degree steel roller and roller frame

Successful Cases

Related product

Garland rollers(3roll)for Underground Structure

Heavy duty steel idler set | GCS

UHMWPE/Polyethylene Roller | GCS

Related article

GCS belt conveyor types and application principle

Roller Conveyor Manufacturing and Supply by (GCS)Global Conveyor Supplies

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

Tell Us Your Requirement About Conveyor Roller .Contact us Now!

Global Conveyor Supplies Company Limited (GCS) conveyor rollers suppliers is specialized in manufacturing selling various idlers for bulk material conveying equipment, galvanized rollers for light industrial continuous conveying equipment, roller conveying systems, spare parts, and related peripheral hardware products. GCS After 26 years of practice adopts advanced technology in its manufacturing operations to implement automatic mechanical production: Automated mechanical roller line, drumline, bracket line: CNC machine tools; Automatic welding robot arm; CNC automatic tapping machine; Data control punching machine; shaft processing line; Metal stamping production line. It also has obtained an ISO9001:2015 quality management system certificate. Our company obtained the industrial production license issued by the General Administration of Quality Supervision, Inspection Products are widely used in bone transportation, thermal power generation, ports, cement plants, coal mines, and metallurgy, as well as light transportation, storage, industry, food, medical and other industries.

Tell Us Your Requirement About Trough Idler .Contact us Now!

Process Flow

Tell Us Your Requirement About Trough Idler .Contact us Now!

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

Tell Us Your Requirement About Coneyor Idler .Contact us Now!

The customer communication

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and skilled IT group, we could offer you technical support on pre-sales & after-sales support for Factory Outlets Steel Rollers - Wholesale Mining Equipment Conveyor Trough Impact Roller | GCS – GCS , The product will supply to all over the world, such as: Georgia, Melbourne, Jordan, Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we provide customized & personalized services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.